Market Overview

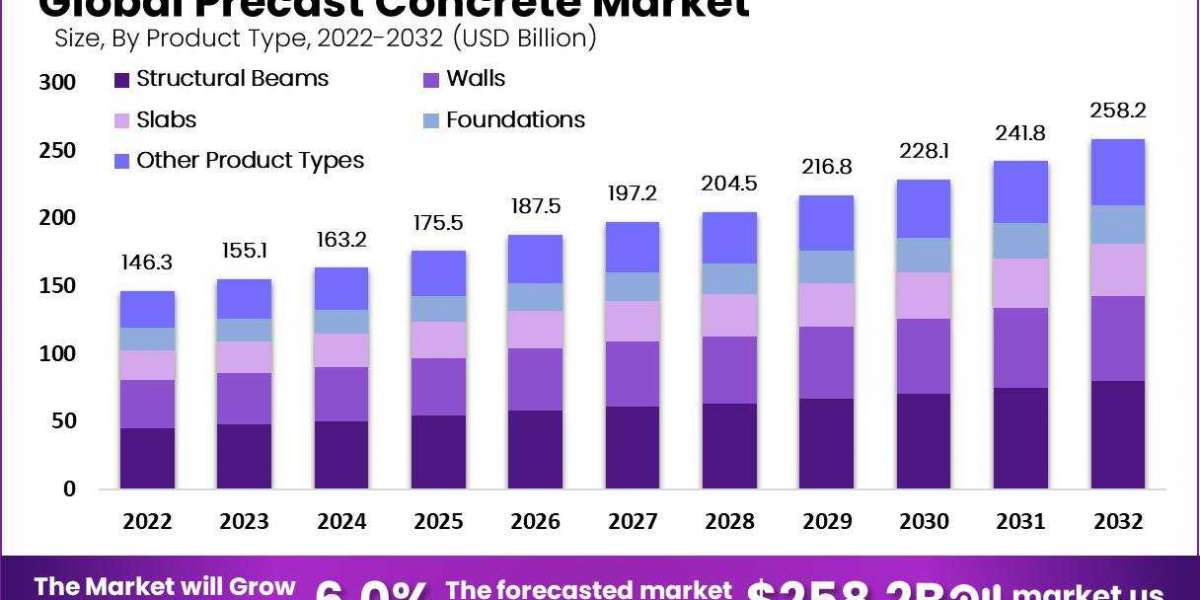

The global Precast Concrete market was valued at USD 146.3 billion in 2022 and is projected to reach USD 258.2 billion by 2032. During the period 2023 to 2032, the highest compound annual growth rate (CAGR) is estimated at 6.0%.

The precast concrete market has witnessed significant growth in recent years, driven by various factors such as urbanization, infrastructure development, and the increasing demand for sustainable construction materials. Precast concrete refers to the process of manufacturing concrete products in a controlled environment, away from the construction site, and then transporting them to the desired location for installation.

Top Key Players

- Boral

- LafargeHolcim

- Gulf Precast

- Olson Precast Company

- Larsen Toubro Limited

- CEMEX

- Forterra

- Tindall Corporation

- Spancrete

- Elementbau Osthessen GmbH Co., ELO KG

- Bouygues Construction

- Balfour Beatty

- Oldcastle Precast

- Other Key Players

Get a free Sample Copy of This Report @https://market.us/report/precast-concrete-market/#requestSample

Key Market Segment

Product Type

- Foundations

- Structural Beams

- Slabs

- Walls

- Other Product Types

Application

- Structural Building Components

- Architectural Building Components

- Transportation Products

- Waste Water Handling Products

- Other Applications

End-user

- Residential

- Non-Residential

Drivers:

- Cost-effectiveness: Precast concrete offers cost advantages due to its efficient manufacturing process, reduced labor requirements, and faster construction time.

- Quality and durability: Precast concrete products are manufactured under controlled conditions, ensuring high quality and durability.

- Sustainability: Precast concrete is an environmentally friendly construction material, as it reduces waste, uses recycled materials, and has a longer lifespan.

- Speed of construction: Precast concrete components can be manufactured off-site and then quickly assembled on-site, leading to faster project completion.

- Design flexibility: Precast concrete allows for a wide range of design options, enabling architects and engineers to create unique and aesthetically pleasing structures.

Restraints:

- Transportation and logistics: Precast concrete components are heavy and require careful transportation, which can be challenging and costly, especially for long-distance projects.

- Initial investment: Setting up a precast concrete manufacturing facility requires significant capital investment, which may deter some potential market entrants.

- Limited customization: While precast concrete offers design flexibility, there are limitations in terms of customization compared to cast-in-place concrete.

Opportunities:

- Transportation and logistics: Precast concrete components are heavy and require careful transportation, which can be challenging and costly, especially for long-distance projects.

- Initial investment: Setting up a precast concrete manufacturing facility requires significant capital investment, which may deter some potential market entrants.

- Limited customization: While precast concrete offers design flexibility, there are limitations in terms of customization compared to cast-in-place concrete.

Challenges:

- Transportation and logistics: Precast concrete components are heavy and require careful transportation, which can be challenging and costly, especially for long-distance projects.

- Initial investment: Setting up a precast concrete manufacturing facility requires significant capital investment, which may deter some potential market entrants.

- Limited customization: While precast concrete offers design flexibility, there are limitations in terms of customization compared to cast-in-place concrete.

Top 5 Trends Propelling Sales:

- Green Building Practices: The increasing emphasis on sustainable construction practices is driving the demand for precast concrete. Precast concrete offers environmental benefits such as reduced energy consumption, lower carbon emissions, and the use of recycled materials. As green building certifications and regulations become more prevalent, the adoption of precast concrete is expected to grow.

- Infrastructure Development: Governments worldwide are investing in infrastructure development to support economic growth. Precast concrete is being widely used in the construction of bridges, highways, tunnels, and other infrastructure projects due to its durability, speed of construction, and cost-effectiveness. The demand for precast concrete in the infrastructure sector is expected to continue growing.

- Technological Advancements: The precast concrete industry is witnessing technological advancements that enhance efficiency and productivity. Automation, robotics, and digitalization are being integrated into the manufacturing process, resulting in improved quality control, faster production, and reduced labor requirements. These advancements are attracting more customers to choose precast concrete solutions.

- Modular Construction: The trend towards modular construction is driving the demand for precast concrete. Modular construction involves the use of precast concrete components that are manufactured off-site and then assembled on-site. This approach offers benefits such as faster construction time, reduced labor costs, and improved quality control. The versatility and design flexibility of precast concrete make it an ideal choice for modular construction projects.

- Urbanization and Population Growth: Rapid urbanization and population growth in many regions are driving the need for affordable and sustainable housing solutions. Precast concrete offers a viable solution for meeting this demand due to its cost-effectiveness, durability, and design flexibility. The ability to construct multi-story buildings quickly using precast concrete components makes it an attractive option for urban housing projects.

Technological innovations:

- 3D Printing: 3D printing, also known as additive manufacturing, is revolutionizing the precast concrete market. It allows for the creation of complex and customized designs with precision and efficiency. 3D printing enables the production of intricate precast concrete components, reducing material waste and labor requirements. This technology also offers the potential for on-site printing, eliminating the need for transportation and logistics.

- Automation and Robotics: Automation and robotics are being increasingly integrated into precast concrete manufacturing processes. Robotic arms and automated systems are used for tasks such as concrete mixing, casting, and finishing. These technologies improve productivity, enhance quality control, and reduce labor costs. Automation also enables the production of precast concrete components with consistent dimensions and finishes.

- Digitalization and Building Information Modeling (BIM): Digitalization and BIM are transforming the precast concrete industry by streamlining design, collaboration, and project management processes. BIM software allows for the creation of detailed 3D models that facilitate accurate visualization, clash detection, and coordination among various stakeholders. Digitalization also enables the integration of precast concrete design data with manufacturing and construction processes, improving efficiency and reducing errors.

- Advanced Materials and Mix Designs: Technological advancements have led to the development of advanced materials and mix designs for precast concrete. These materials offer improved strength, durability, and sustainability. For example, the use of high-performance concrete mixes, fiber-reinforced concrete, and self-consolidating concrete (SCC) enhances the structural integrity and performance of precast concrete components.

- IoT and Sensors: The Internet of Things (IoT) and sensor technologies are being utilized in precast concrete applications to monitor and optimize performance. Sensors embedded in precast concrete components can provide real-time data on factors such as temperature, moisture, and structural integrity. This data helps in quality control, predictive maintenance, and structural health monitoring, ensuring the longevity and safety of precast concrete structures.

Contact us:

Global Business Development Team: Market.us

Market.us (Powered By Prudour Pvt. Ltd.)

Send Email: inquiry@market.us

Address: 420 Lexington Avenue, Suite 300 New York City, NY 10170, United States

Tel: +1 718 618 4351, +91 78878 22626