instaswifttrade.com is now instaswifttrade.net | #instaswifttrade.com is now instaswifttrade.net

Discover posts

Explore captivating content and diverse perspectives on our Discover page. Uncover fresh ideas and engage in meaningful conversations

Protein Ingredients Market Report Includes Dynamics, Products, and Application 2024 – 2033 | #protein Ingredients Market Share # Protein Ingredients Market Demand # Protein Ingredients Market Scope # Protein Ingredients Market Analysis # Protein Ingredients Market Trend

Understanding the Applications and Advantages of Inconel 600 Pipes and Tubes

Inconel 600 is a highly universal alloy renowned for its excellent resistance to oxidation, and high temperatures. This makes it a preferred choice for demanding applications where reliability and performance are critical. When considering Inconel 600 pipes, understanding their specific applications and advantages becomes crucial for making informed decisions.

Applications of Inconel 600 Pipes and Tubes:

Aerospace: Used in aircraft ducting systems, combustion chambers, and engine exhaust systems due to its high strength and resistance to heat and oxidation.

Chemical Processing: Ideal for handling corrosive acids and environments where high temperature and pressure resistance are required, such as in chemical reactors and processing equipment.

Heat Treatment Industry: Utilized in furnace muffles, radiant tubes, and other components where resistance to high temperatures and thermal cycling is essential.

Oil and Gas: Applications include downhole tubing and components in oil refineries, where resistance to sour gas and other corrosive substances is critical.

Advantages of Inconel 600 Pipes and Tubes:

Corrosion Resistance: Offers excellent resistance to corrosion in both reducing and oxidizing environments, including high-purity water and chloride ion stress corrosion cracking.

High-Temperature Strength: Maintains its mechanical properties over a wide temperature range, from cryogenic to elevated temperatures exceeding 2000°F (1093°C).

Versatility in Fabrication: Can be easily welded, formed, and machined, allowing for complex designs and configurations in piping systems.

Longevity and Reliability: Known for its durability and longevity in harsh operating conditions, reducing maintenance and replacement costs over time.

Manufacturing of Inconel 600 Pipes and Tubes:

Production Methods: Typically manufactured using seamless or welded tubes, ensuring consistency in dimensions and properties.

Quality Control: Rigorous testing and inspection ensure adherence to industry standards and specifications, guaranteeing reliability in critical applications.

Conclusion:

Inconel 600 tubes stand out for their robustness, reliability, and versatility across various industries where corrosion resistance and high-temperature strength are paramount. Understanding their applications and advantages helps industries make informed choices, ensuring optimal performance and longevity in challenging environments.

Understanding the Applications and Advantages of Inconel 600 Pipes and Tubes

Inconel 600 is a highly universal alloy renowned for its excellent resistance to oxidation, and high temperatures. This makes it a preferred choice for demanding applications where reliability and performance are critical. When considering Inconel 600 pipes, understanding their specific applications and advantages becomes crucial for making informed decisions.

Applications of Inconel 600 Pipes and Tubes:

Aerospace: Used in aircraft ducting systems, combustion chambers, and engine exhaust systems due to its high strength and resistance to heat and oxidation.

Chemical Processing: Ideal for handling corrosive acids and environments where high temperature and pressure resistance are required, such as in chemical reactors and processing equipment.

Heat Treatment Industry: Utilized in furnace muffles, radiant tubes, and other components where resistance to high temperatures and thermal cycling is essential.

Oil and Gas: Applications include downhole tubing and components in oil refineries, where resistance to sour gas and other corrosive substances is critical.

Advantages of Inconel 600 Pipes and Tubes:

Corrosion Resistance: Offers excellent resistance to corrosion in both reducing and oxidizing environments, including high-purity water and chloride ion stress corrosion cracking.

High-Temperature Strength: Maintains its mechanical properties over a wide temperature range, from cryogenic to elevated temperatures exceeding 2000°F (1093°C).

Versatility in Fabrication: Can be easily welded, formed, and machined, allowing for complex designs and configurations in piping systems.

Longevity and Reliability: Known for its durability and longevity in harsh operating conditions, reducing maintenance and replacement costs over time.

Manufacturing of Inconel 600 Pipes and Tubes:

Production Methods: Typically manufactured using seamless or welded tubes, ensuring consistency in dimensions and properties.

Quality Control: Rigorous testing and inspection ensure adherence to industry standards and specifications, guaranteeing reliability in critical applications.

Conclusion:

Inconel 600 tubes stand out for their robustness, reliability, and versatility across various industries where corrosion resistance and high-temperature strength are paramount. Understanding their applications and advantages helps industries make informed choices, ensuring optimal performance and longevity in challenging environments.

Lisp Solutions: Evaluating ProgrammingHomeworkHelp.com and ProgrammingAssignmentHelper.com | #lispassignmenthelp #programmingassignmenthelp #students #university #helpwithlispassignment

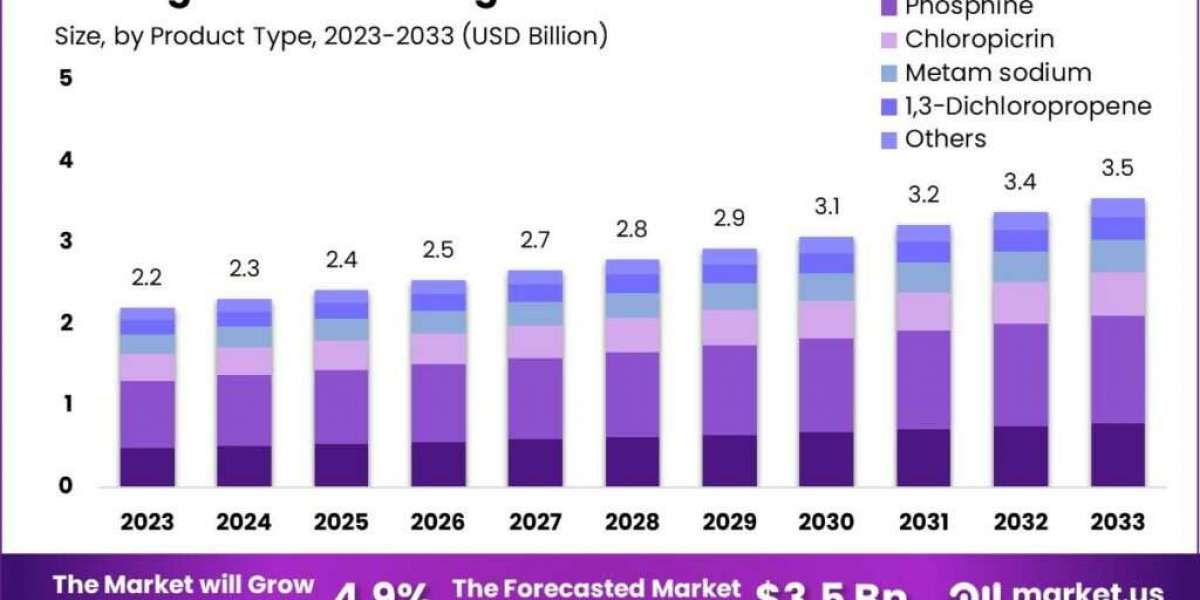

Agricultural Fumigants Market: Innovations in Soil Treatment | #agricultural Fumigants Market #post-Harvest Losses