White cast iron is a versatile material known for its exceptional hardness and wear resistance, making it suitable for a wide range of industrial applications. Here’s a comprehensive overview of what white cast irons are, their properties, common applications, and the advantages they offer:

1. What are White Cast Irons?

White cast irons are a type of cast iron characterized by their white fracture surface due to the presence of cementite. Unlike gray cast iron, which has graphite flakes in its microstructure, white cast irons have a predominantly pearlitic matrix with embedded carbides.

2. Properties of White Cast Irons:

Hardness: White cast irons are extremely hard and exhibit excellent abrasion resistance, making them ideal for applications involving wear.

Brittleness: They are generally brittle compared to other cast irons, which can limit their use in applications requiring toughness.

Wear Resistance: Their high hardness and carbide content make them highly resistant to abrasion, making them suitable for parts subjected to sliding wear and impact.

3. Common Applications:

White cast irons find applications in various industries where wear resistance and hardness are critical:

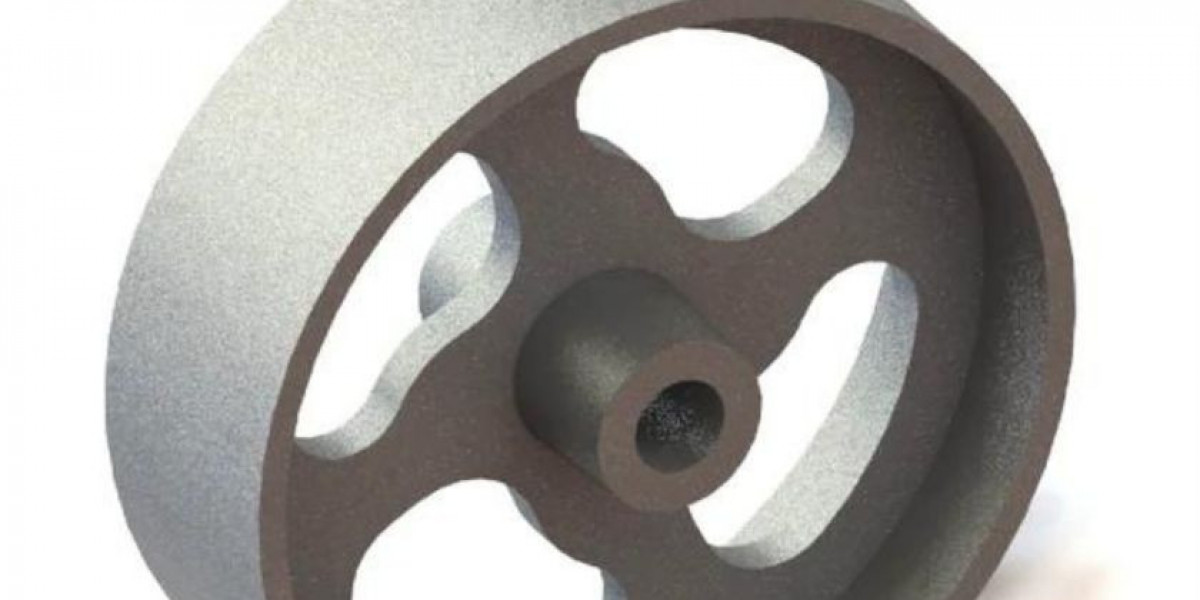

Mining and Quarrying: Used for crusher parts, excavator teeth, and wear plates in mining equipment.

Oil and Gas: Valve seats, pump components, and drilling tools benefit from their wear-resistant properties.

Automotive: Brake drums, cylinder liners, and gears where high wear resistance is needed.

4. Advantages of White Cast Irons:

High Wear Resistance: Their ability to withstand abrasion makes them indispensable in industries where equipment longevity is crucial.

Cost-Effectiveness: White cast irons offer a cost-effective solution due to their durability and reduced need for replacement.

5. Machinability and Weldability:

Machinability: While white cast irons are hard, they can be machined with carbide tools at low speeds and feeds.

Weldability: Welding white cast irons can be challenging due to their high carbon content and brittleness, requiring preheating and post-weld heat treatment for successful welds.

6. Types of White Cast Irons:

High Chrome White Irons: Contains chromium to improve wear resistance and corrosion resistance.

Ni-Hard White Irons: Nickel and chromium alloyed white cast irons used in high abrasion applications.

7. Maintenance and Considerations:

Regular inspection and maintenance are crucial to monitor wear and prevent unexpected failures.

Proper handling and machining practices are essential to maximize the performance and longevity of components made from white cast irons.

In conclusion, white cast irons offer unparalleled hardness and wear resistance, making them indispensable in industries where durability and performance under abrasive conditions are paramount. Understanding their properties, applications, and maintenance requirements can help optimize their use in various engineering applications.