In the realm of pharmaceuticals and chemical synthesis, understanding production costs and processes is crucial for informed decision-making. Acetylcysteine, a vital compound known for its mucolytic and antioxidant properties, is no exception. A comprehensive production cost analysis sheds light on the intricate workings of its manufacturing, offering insights essential for industry stakeholders.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/acetylcysteine/request-sample

Procurement Resource Assessment of Acetylcysteine Production Process:

Procurement Resource provides a meticulous evaluation of the acetylcysteine production process. Their assessment covers the entire production chain, from raw material procurement to final product formulation. This thorough analysis ensures clarity on resource allocation, process efficiency, and cost-effectiveness.

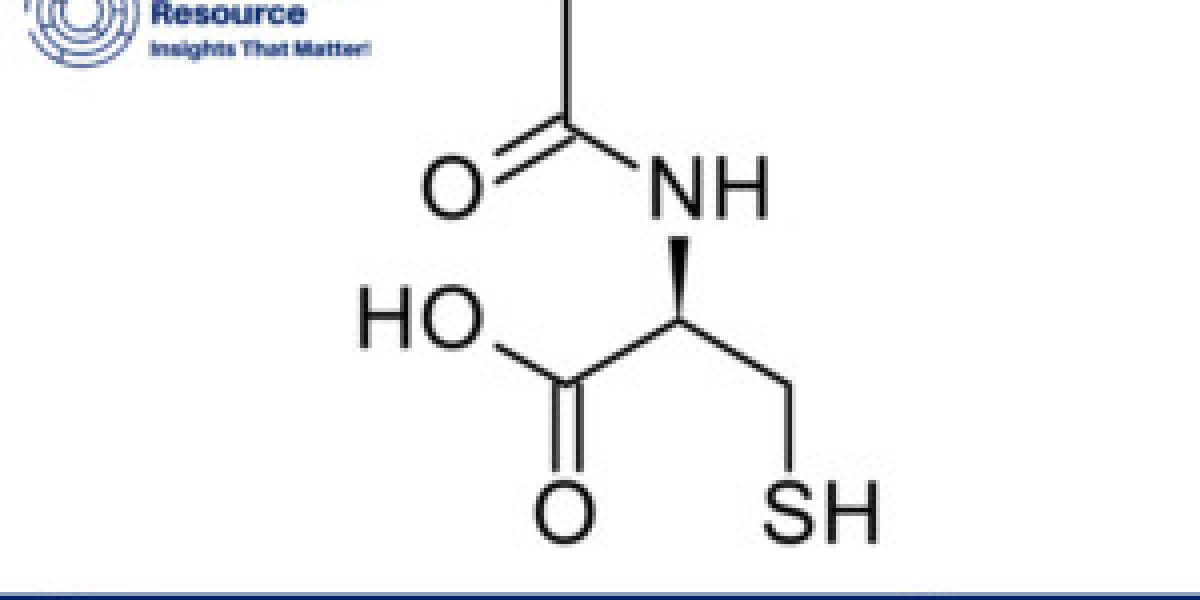

Product Definition:

Acetylcysteine, also known as N-acetylcysteine (NAC), is a derivative of the amino acid L-cysteine. It finds extensive application in pharmaceuticals, primarily for treating acetaminophen overdose and respiratory conditions like chronic bronchitis. The compound's versatile nature extends its use into various medical and therapeutic formulations.

Market Drivers:

Several factors propel the demand and production of acetylcysteine. Increasing prevalence of respiratory diseases worldwide, coupled with its role in mitigating liver damage from acetaminophen overdose, drives its pharmaceutical application. Moreover, ongoing research into its antioxidant properties continues to expand its potential in healthcare and wellness sectors.

Raw Materials Requirements:

The production of acetylcysteine necessitates a blend of raw materials sourced for their purity and quality. Key components include L-cysteine, acetic anhydride, and various solvents and catalysts. Each ingredient's quality impacts the final product's efficacy and safety, underscoring the importance of stringent procurement practices.

Costs and Key Process Information:

Analyzing the cost structure of acetylcysteine production reveals insights into cost drivers and optimization opportunities. Key cost components include raw material procurement, labor costs, energy consumption, and regulatory compliance. Understanding these elements facilitates strategic decision-making, ensuring competitiveness in the market.

Looking for an exhaustive and personalized report that could significantly substantiate your business:

For stakeholders seeking in-depth insights into acetylcysteine production, a personalized report is indispensable. It provides a tailored examination of production processes, cost dynamics, and market trends specific to your business needs. Such a report empowers stakeholders to make informed decisions, optimize operations, and seize growth opportunities in the competitive pharmaceutical landscape.

Conclusion:

In conclusion, the Acetylcysteine Production Cost Analysis Report offers a comprehensive view of the production processes, cost structures, and market dynamics shaping the acetylcysteine industry. Whether for pharmaceutical manufacturers, suppliers, or investors, this report serves as a valuable tool for navigating complexities and driving strategic initiatives forward.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA