Introduction

The Gentamine Sulfate Production Process with Cost Analysis report provides an exhaustive look into the methods and economic considerations of manufacturing Gentamine Sulfate. This antibiotic is pivotal in combating a wide range of bacterial infections, making it essential in the medical and pharmaceutical sectors. Our comprehensive report delves into the production processes, evaluates market drivers, and offers detailed insights into cost structures and raw material requirements.

Request Free Sample - https://www.procurementresource.com/production-cost-report-store/gentamine-sulfate/request-sample

Procurement Resource Assessment of the Gentamine Sulfate Production Process

Conducting a procurement resource assessment is crucial for businesses engaged in or looking to enter the Gentamine Sulfate market. This evaluation encompasses multiple facets:

Raw Material Sourcing: The primary raw materials for producing Gentamine Sulfate include gentamicin base and sulfuric acid. Ensuring a consistent and cost-effective supply of these materials is vital for maintaining production efficiency and controlling costs.

Production Technologies: Gentamine Sulfate can be synthesized through various methods, including fermentation and chemical synthesis. The choice of technology affects production efficiency, product quality, and environmental impact, making it a key component of the procurement strategy.

Supply Chain Management: Effective logistics and supply chain strategies are essential for minimizing disruptions and ensuring timely delivery of raw materials and finished products. This includes transportation, storage, and inventory management.

Regulatory Compliance: Adhering to stringent pharmaceutical regulations is critical in the production of Gentamine Sulfate. Compliance with Good Manufacturing Practices (GMP) and other regulatory standards ensures product safety and efficacy, which are paramount in the pharmaceutical industry.

Understanding Gentamine Sulfate

Gentamine Sulfate is a potent antibiotic used extensively in the treatment of various bacterial infections. Here’s a closer look at its properties and applications:

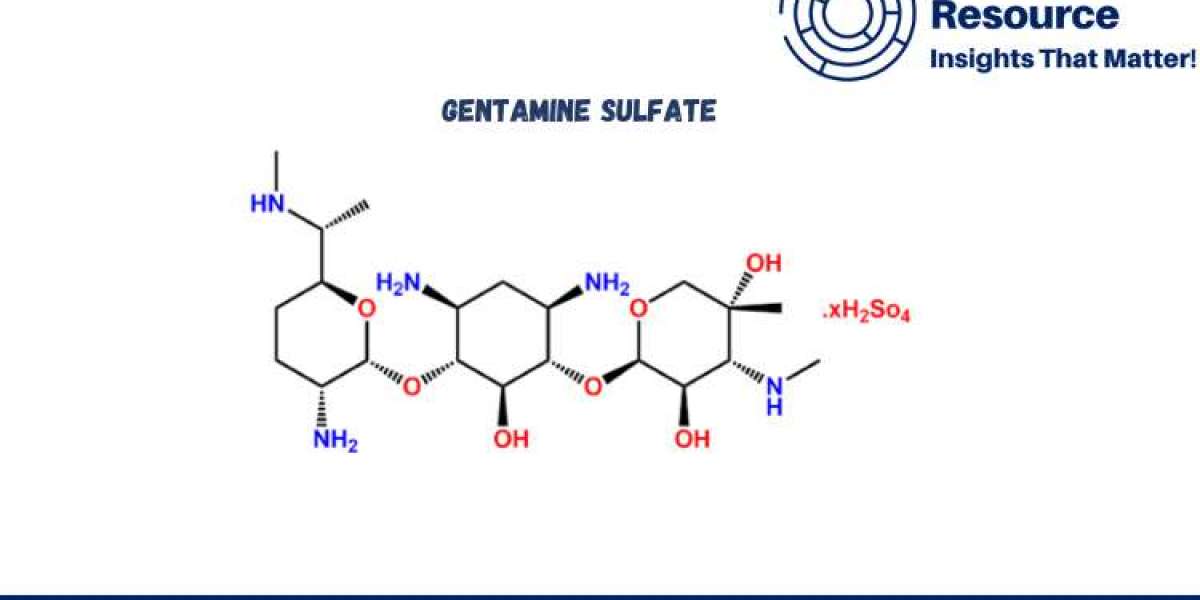

Chemical Properties: Gentamine Sulfate is a white or off-white powder that is soluble in water. It is the sulfate salt form of gentamicin, a mixture of related compounds known for their broad-spectrum antibacterial activity.

Applications: It is commonly used to treat infections caused by Gram-negative bacteria and certain Gram-positive bacteria. Gentamine Sulfate is frequently used in hospital settings for serious infections, including sepsis, respiratory tract infections, urinary tract infections, and skin infections.

Mechanism of Action: Gentamine Sulfate works by binding to the bacterial ribosome, inhibiting protein synthesis and leading to bacterial cell death. Its effectiveness and relatively low cost make it a widely used antibiotic in both human and veterinary medicine.

Key Market Drivers

Several factors are driving the demand for Gentamine Sulfate in the global market. Understanding these drivers is crucial for stakeholders looking to capitalize on the growth opportunities in this sector:

Rising Incidence of Bacterial Infections: The global increase in bacterial infections, including hospital-acquired infections and antibiotic-resistant strains, is a significant driver for Gentamine Sulfate. Its broad-spectrum activity makes it a valuable tool in treating serious infections.

Expansion of Healthcare Services: As healthcare services expand, especially in emerging markets, the demand for effective antibiotics like Gentamine Sulfate continues to grow. Improvements in healthcare infrastructure and increased access to medical services contribute to this rising demand.

Veterinary Applications: Gentamine Sulfate is widely used in veterinary medicine to treat infections in livestock and pets. The growing pet care industry and the need for effective animal health solutions drive demand in this segment.

Advancements in Drug Delivery Systems: Innovations in drug delivery systems, such as topical formulations and combination therapies, enhance the application scope of Gentamine Sulfate. These advancements improve patient compliance and therapeutic outcomes, further boosting demand.

Regulatory Approvals and Market Expansion: Regulatory approvals for new indications and formulations of Gentamine Sulfate, along with strategic market expansions by pharmaceutical companies, contribute to its growing demand. These factors facilitate the availability and use of Gentamine Sulfate in various regions.

Raw Materials Requirements

The production of Gentamine Sulfate involves several key raw materials, each contributing to the final product’s quality and production cost:

Gentamicin Base: The primary active ingredient, gentamicin base, is typically obtained through fermentation processes involving specific strains of Micromonospora or Streptomyces bacteria. The quality and yield of gentamicin base are crucial determinants of the overall production efficiency and cost.

Sulfuric Acid: Sulfuric acid is used to convert gentamicin base into its sulfate form, which enhances its solubility and stability. The purity and concentration of sulfuric acid are important factors in the synthesis process.

Nutrient Media: In fermentation-based production, nutrient media are essential for the growth and metabolism of the producing microorganisms. The composition and quality of these media directly impact the yield and quality of gentamicin base.

Chemical Reagents: Various chemical reagents are required for the extraction, purification, and conversion processes in Gentamine Sulfate production. These include solvents, catalysts, and stabilizers that ensure the efficiency and quality of the production process.

Energy and Utilities: Significant energy inputs are needed for the fermentation, extraction, and drying processes. Efficient energy management and sourcing strategies are crucial for cost control and sustainability in production.

Costs and Key Process Information

Understanding the cost structure and key processes involved in Gentamine Sulfate production is essential for evaluating the feasibility and profitability of manufacturing this antibiotic. Here are the primary considerations:

Capital Expenditures (CapEx): Initial investments include setting up fermentation facilities, purchasing advanced extraction and purification equipment, and establishing infrastructure for raw material handling and storage. The scale and technology of the production plant significantly influence the CapEx.

Operational Expenditures (OpEx): Ongoing costs encompass raw material procurement, energy consumption, labor, maintenance, and compliance with regulatory standards. Efficient production processes and economies of scale can help in reducing these costs.

Fermentation and Extraction Process: The production process typically involves fermenting microorganisms to produce gentamicin base, followed by extraction and purification steps to isolate the active compound. Finally, sulfuric acid is used to convert gentamicin base into its sulfate form.

Product Quality and Yield: The quality of Gentamine Sulfate is determined by its purity, potency, and consistency. Achieving high yield and maintaining product quality are crucial for meeting regulatory standards and market demands.

Regulatory Compliance: Adhering to Good Manufacturing Practices (GMP) and other regulatory standards is essential in the pharmaceutical industry. Compliance ensures product safety and efficacy, which are critical for gaining market approval and consumer trust.

Looking for an Exhaustive and Personalized Report?

In the complex and competitive landscape of Gentamine Sulfate production and its applications, having access to comprehensive, accurate, and tailored insights is invaluable. Whether you are a manufacturer, investor, or stakeholder in the pharmaceutical industry, a detailed report customized to your specific needs can significantly support your business decisions.

Customized Market Insights: Obtain detailed analysis of market trends, drivers, and forecasts aligned with your business objectives. Understand how shifts in the market could impact your operations and identify potential growth opportunities.

In-depth Cost Analysis: Gain a thorough understanding of the cost structure involved in Gentamine Sulfate production, including CapEx and OpEx. This analysis aids in financial planning, investment strategies, and cost optimization.

Supply Chain Evaluation: Assess your raw material sourcing and supply chain strategies to ensure efficiency and cost-effectiveness. Identify and address potential supply chain bottlenecks and risks.

Regulatory and Compliance Insights: Stay compliant with evolving pharmaceutical regulations and implement sustainable practices. These insights help you manage compliance costs and enhance your market positioning.

Technological Advancements: Keep updated with the latest technological developments in Gentamine Sulfate production that can improve your production efficiency and reduce costs.

Conclusion

Gentamine Sulfate is a critical antibiotic in the fight against bacterial infections, with widespread applications in human and veterinary medicine. Understanding the production processes, market drivers, cost structures, and raw material requirements is vital for businesses looking to succeed in this competitive pharmaceutical sector.

For stakeholders in the Gentamine Sulfate industry, investing in detailed market insights and cost analysis is essential for making informed, strategic decisions. Whether you are looking to expand your production capabilities, optimize your supply chain, or explore new market opportunities, a comprehensive and personalized report can significantly support your business strategy.

If you’re seeking exhaustive and tailored insights into the Gentamine Sulfate market, our team of experts is here to provide the information you need. We offer customized assessments that help you navigate the complexities of Gentamine Sulfate production and capitalize on the opportunities in this vital market.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Number: USA Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA