Report Overview

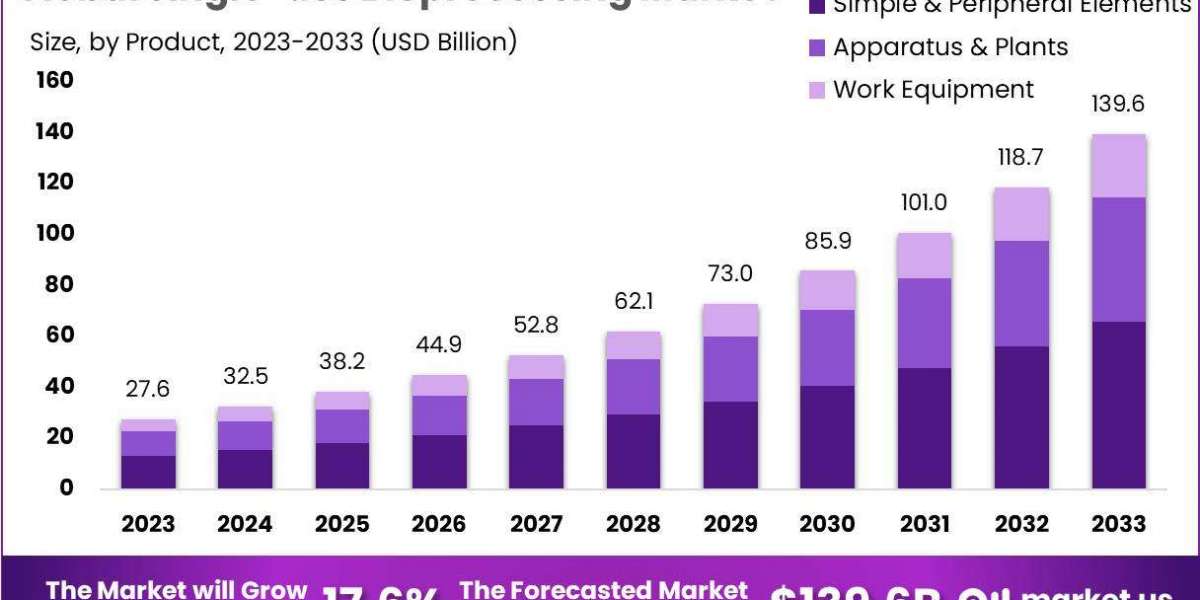

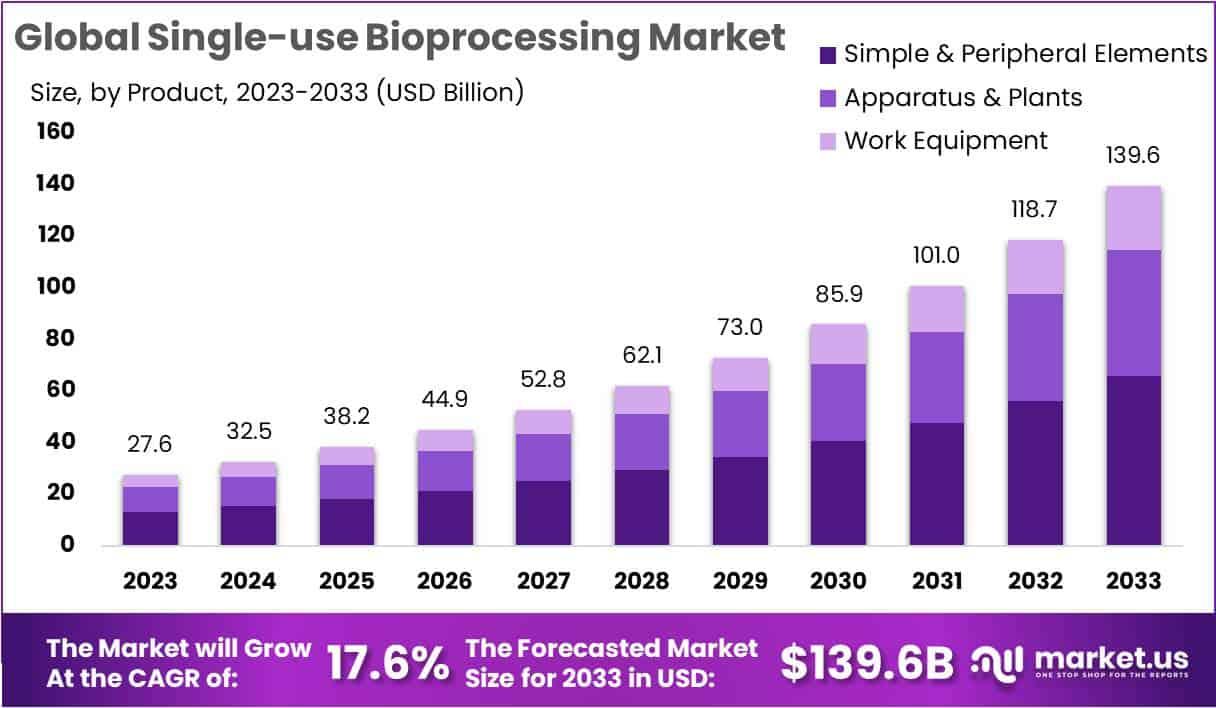

The Single-use Bioprocessing Market Size is anticipated to reach approximately USD 139.6 Billion by 2033, exhibiting substantial growth from its estimated value of USD 27.6 Billion in 2023. This remarkable expansion is forecasted to occur at a Compound Annual Growth Rate (CAGR) of 17.6% throughout the forecast period spanning from 2024 to 2033.

Key Takeaways

Market Size and Growth: In 2023, the single-use bioprocessing market is valued at USD 27.6 billion, with projections indicating it will reach USD 139.6 billion by 2033. This reflects a strong compound annual growth rate (CAGR) of 17.6%.

Market Dominance: North America is at the forefront, holding a 36.8% market share, which translates to USD 10.15 billion. This shows the significant adoption of single-use bioprocessing technologies in the region.

Product Leadership: Simple & Peripheral Elements dominate the market with over 47.2% share, highlighting their essential role in advancing the industry.

Workflow Performance: Upstream Bioprocessing leads with a significant 55.9% market share, underscoring its critical role in setting the stage for successful bioproduction.

End-use Significance: Biopharmaceutical Manufacturers have a commanding presence, with a 56.9% market share, emphasizing the importance of single-use technologies in their manufacturing processes.

Regional Analysis: North America remains a strong player in the Single-use Bioprocessing Market, capturing over 36.8% of the market share and boasting a market value of USD 10.1 billion.

Get a sample copy of the report to know more https://market.us/report/single-use-bioprocessing-market/https://market.us/report/single-use-bioprocessing-market/request-sample/

Key Market Segments

Product

- Simple & Peripheral Elements

- Tubing, Filters, Connectors, & Transfer Systems

- Bags

- Sampling Systems

- Probes & Sensors

- pH Sensor

- Oxygen Sensor

- Pressure Sensors

- Temperature Sensors

- Conductivity Sensors

- Flow Sensors

- Others

- Others

- Apparatus & Plants

- Bioreactors

- Mixing, Storage, & Filling Systems

- Filtration System

- Chromatography Systems

- Pumps

- Others

- Work Equipment

- Cell Culture System

- Syringes

- Others

Workflow

- Upstream Bioprocessing

- Fermentation

- Downstream Bioprocessing

End-use

- Biopharmaceutical Manufacturers

- CMOs & CROs

- In-house Manufacturers

- Academic & Clinical Research Institutes

Key Regions

- North America (The US, Canada, Mexico)

- Western Europe (Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, Rest of Western Europe)

- Eastern Europe (Russia, Poland, The Czech Republic, Greece, Rest of Eastern Europe)

- APAC (China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, Rest of APAC)

- Latin America (Brazil, Colombia, Chile, Argentina, Costa Rica, Rest of Latin America)

- Middle East & Africa (Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, Rest of MEA)

Market Key Players

- Sartorius AG

- Danaher Corp.

- Thermo Fisher Scientific Inc.

- Merck KGaA

- Avantor Inc.

- Eppendorf SE

- Corning Inc.

- Boehringer Ingelheim International GmbH

- Lonza

- Infors AG

- PBS Biotech Inc.

If You Have Any Questions About This Report, Please Reach Out to Us

Driver

Cost Efficiency:

Disposable bioreactors eliminate the need for time-consuming cleaning and sterilization procedures thus bringing down the operating expenses significantly as well as improving the throughput.

Flexibility and Scalability:

Compared to traditional operations, these systems are flexible and more scalable hence enabling the manufacturers to respond to the changes in the demand in the production process and scale up the manufacturing process in the shortest time possible.

Reduced Risk of Contamination:

Its application of disposable settings reduces batch inter contamination and increases products’ quality and safety.

Technological Advancements:

Constant technological advancements in single-use systems including better bioreactors and filters contribute more to the market growth by making the systems more effective.

Restraints:

High Initial Setup Costs:

The capital cost for the initial installation of these single-use bioprocessing systems could be expensive and thus any technology that is initially expensive will always be a hard sell for the small companies.

Environmental Concerns:

The disposal of single-use parts leads to the production of plastics which are dangerous to the environment and thus, there appears a call to resort to using more sustainable components for every device.

Limited Large-Scale Production:

A single-use system is generally used in small to middle-scale production and has limitations in large-scale requirements that as bioproduction.

Regulatory Challenges:

There is often a significant level of complexity in terms of the single-use regulatory framework which can differ significantly from country to country.

Opportunities:

Expanding Biopharmaceutical Industry:

The need for biopharmaceuticals in the global markets including monoclonal antibodies and vaccines is being experienced and is a perfect opportunity to encourage the single-use bioprocessing system.

Emerging Markets:

Growth in the healthcare industry in new development regions are good market opportunity for single-use bioprocessing technologies.

Sustainable Innovations:

Concerns for the environment due to single-use elements may be tackled effectively by continued innovation in disposable material and recycling processes of these products’ individual components.

Personalized Medicine:

New approaches are becoming more and more relevant, such as the growth in the specialty of personalized medicine where the relational small batch production of therapeutic methods matches Single-use bioprocessing systems market needs.

Contact Us :

420 Lexington Avenue, Suite 300 New York City, NY 10170,

United States

Phone: +1 718 618 4351 (International),+91 78878 22626 (Asia)

Email:inquiry@market.us