In today's fast-paced manufacturing landscape, staying ahead of the competition often depends on innovative techniques. One such method that has gained significant traction is Rapid Aluminum Tooling. Ahead in this post, we'll delve into how you can unlock the full potential of this game-changing technology.

Understanding Rapid Aluminum Tooling

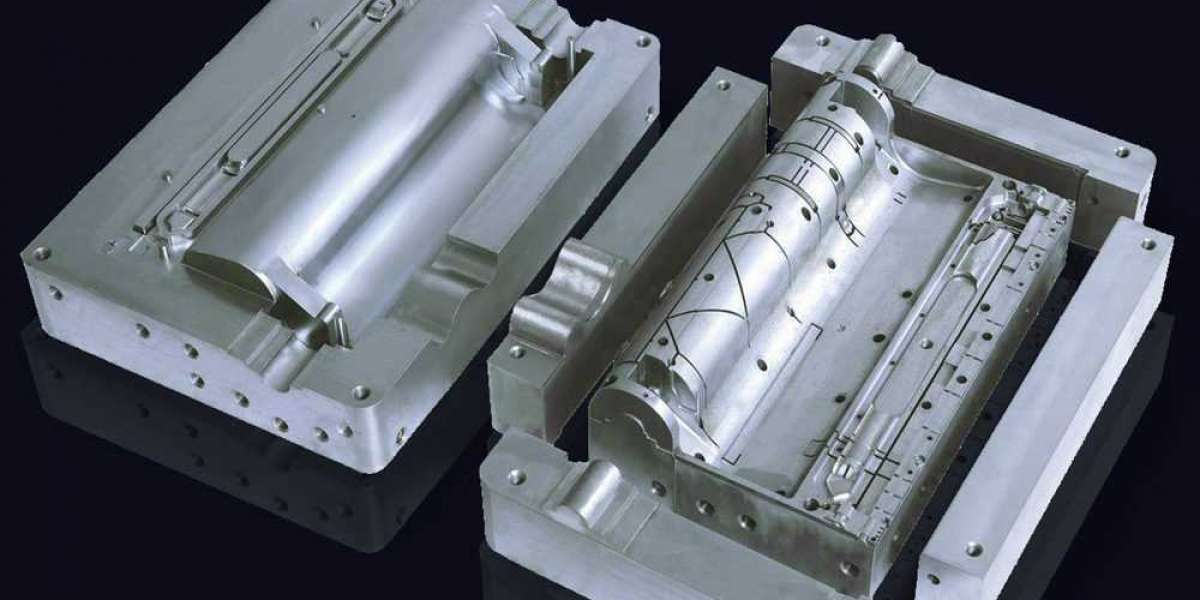

Rapid aluminum tooling is a modern manufacturing technique that uses aluminum molds for swift prototyping and part production. Rapid Aluminum Tooling provides a more affordable and efficient solution compared to traditional methods, which are often slow and costly.

Furthermore, aluminum molds boast exceptional thermal conductivity, which helps control temperatures during production. Their versatility allows them to adapt to intricate designs and complex shapes, making them a valuable asset in various industries. Moreover, it is easy to handle and transport, thanks to its lightweight design.

Advantages of Rapid Aluminum Tooling

Let's explore the primary benefits of rapid aluminum tooling:

1. Cost-effectiveness: Aluminum molds are affordable to produce and maintain, leading to lower initial investment costs.

2. Faster Cycle Times: Lightweight aluminum molds result in quicker production cycles, which significantly reduces lead times.

3. Reduced Energy Consumption: Aluminum's heat transfer properties reduce energy requirements during production.

4. Material Savings: Aluminum's low thermal expansion minimizes material wastage, contributing to sustainability.

5. Corrosion Resistance: Aluminum's natural oxide layer provides corrosion resistance to extend mold life.

Applications and Industries

Rapid aluminum tooling finds applications across various industries:

Industries: Automotive, aerospace, consumer electronics, healthcare, and more.

Automotive Example: Quick prototyping for shorter product development cycles.

Aerospace Example: Rapid creation of lightweight components for aircraft.

Consumer Electronics Example: Fast iterations of electronic device casings.

Key Factors for Success in Rapid Aluminum Tooling

Consider the following factors to make the most of Rapid Aluminum Tooling:

1. Design Optimization: Meticulous design is critical for aluminum tooling, focusing on wall thickness, draft angles, and part geometry.

2. Material Selection: Consider factors like strength, hardness, and thermal conductivity to choose the right aluminum alloy for your project.

3. Collaboration: Work closely with reputed manufacturers like iMold USA, LLC, to fine-tune designs and ensure compatibility with aluminum tooling.

4. Prototyping Strategies: Develop efficient prototype testing strategies to validate designs and make necessary adjustments.

5. Quality Control: Implement stringent quality control measures at all stages to ensure final products meet quality standards.

Best Practices and Tips for Successful Rapid Aluminum Tooling

When venturing into Rapid Aluminum Tooling, keep these best practices in mind:

Prototype Testing: Use prototypes for extensive testing and validation to identify design flaws and improvements.

Quality Control: Implement inspection points during manufacturing to detect issues early and reduce defects.

Documentation: Maintain comprehensive records of design changes, manufacturing processes, and quality checks.

Regular Maintenance: Schedule regular inspections and maintenance for aluminum molds to address wear and tear promptly.

Training: Train your team to handle aluminum tooling effectively, ensuring safety and optimal performance.

Challenges and How to Overcome Them

While rapid aluminum tooling offers numerous advantages, it's essential to address potential challenges proactively to ensure successful implementation:

Aluminum Wear and Tear: Over time, aluminum molds may experience wear and tear due to repeated use. Establish a regular maintenance schedule and conduct thorough inspections to overcome this. Timely maintenance can extend the life of aluminum tooling and minimize production interruptions.

Material Compatibility: Ensure the selected aluminum alloys align perfectly with your specific manufacturing processes and materials. Compatibility issues can be mitigated through meticulous material selection and testing to prevent unexpected complications during production.

Initial Investment: While aluminum tooling offers long-term cost savings, it may require an initial investment in mold creation. To navigate this challenge, carefully assess the return on investment and consider the benefits of reduced production costs and faster turnaround times.

Specialized Knowledge: Effectively leveraging aluminum tooling may require specialized knowledge and expertise. Invest in training for your team to ensure they can handle aluminum tooling safely and efficiently.

Quality Assurance: Maintaining strict quality assurance processes is vital to preventing defects and minimizing rework. Implement comprehensive quality checks and closely monitor production to uphold high-quality standards throughout manufacturing.

Addressing these challenges head-on will help you fully unlock the potential of Rapid Aluminum Tooling and reap the benefits it offers in terms of efficiency and cost-effectiveness.

Final Thoughts

Thus, you can harness the power of rapid aluminum tooling and take your projects to new heights by considering design optimization, material selection, and adhering to best practices.

Explore the possibilities of this technology and stay ahead in the race to innovate and produce high-quality products efficiently. Remember that unlocking the full potential of Rapid Aluminum Tooling can help your manufacturing business achieve the success it deserves.