Refrigerators are an essential part of our daily lives, and they are used in almost every household. The manufacturing process of a refrigerator involves several steps, and one of the critical steps is the creation of a plastic injection mold. In this blog post, Xuzhong will supply you with the manufacturing process of a refrigerator plastic injection mold for sale.

What is a plastic injection mold?

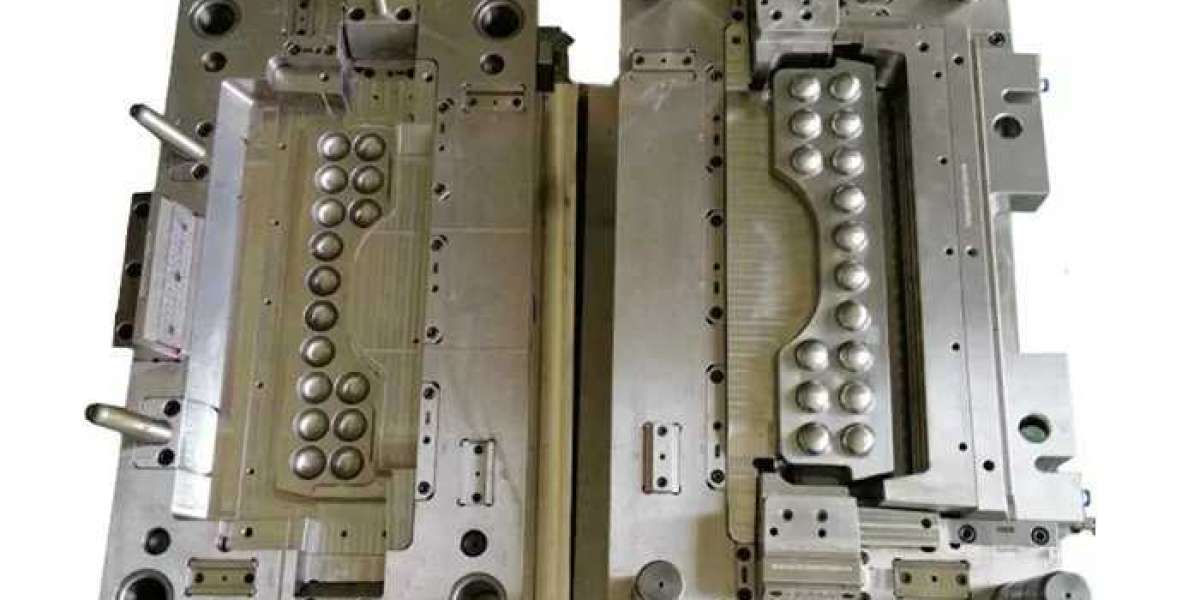

A plastic injection mold is a tool used to produce plastic parts by injecting molten plastic into a mold cavity. The mold is made of two halves, the core, and the cavity. The core is the part of the mold that creates the internal shape of the plastic part, while the cavity creates the external shape.

Manufacturing process of refrigerator plastic injection mold supply

The manufacturing process of a refrigerator plastic injection mold involves several steps, including design, material selection, mold making, and testing.

Design

The first step in the manufacturing process of a refrigerator plastic injection mold is the design. The design process involves creating a 3D model of the mold using computer-aided design (CAD) software. The design must be precise and accurate to ensure that the mold produces high-quality plastic parts.

Material selection

The next step is material selection. The material used to make the mold must be able to withstand high temperatures and pressure. The most commonly used materials for refrigerator plastic injection molds are steel and aluminum. Steel is preferred for its durability and ability to withstand high temperatures, while aluminum is preferred for its lightweight and ability to cool quickly.

Mold making

Once the design and material selection are complete, the mold making process can begin. The mold making process involves several steps, including milling, drilling, and polishing.

Milling

The first step in the mold making process is milling. Milling involves cutting the mold cavity and core into the selected material using a CNC machine. The CNC machine uses a computer program to control the cutting process, ensuring that the mold is precise and accurate.

Drilling

The next step is drilling. Drilling involves creating holes in the mold for the injection nozzles, cooling channels, and ejector pins. The cooling channels are essential as they help to cool the mold quickly, allowing for faster production.

Polishing

The final step in the mold making process is polishing. Polishing involves smoothing the surface of the mold to ensure that the plastic parts produced are of high quality. The polishing process is done manually, and it requires a high level of skill and precision.

Testing

Once the mold is complete, it is tested to ensure that it produces high-quality plastic parts. The testing process involves injecting molten plastic into the mold cavity and checking the quality of the plastic parts produced. Any defects or issues with the mold are identified and corrected before it is used for production.

Conclusion

The manufacturing process of a refrigerator plastic injection mold is a complex process that requires a high level of skill and precision. The mold must be designed accurately, and the material selection must be appropriate to ensure that the mold can withstand high temperatures and pressure. The mold making process involves several steps, including milling, drilling, and polishing, and the mold is tested to ensure that it produces high-quality plastic parts. By following these steps, manufacturers can produce high-quality refrigerator plastic injection molds that can be used for mass production.

https://www.xuzhongmold.com/Manufacturing-process-of-refrigerator-plastic-injection-mold.html