Tips and tricks for successful composite printer plastic molding

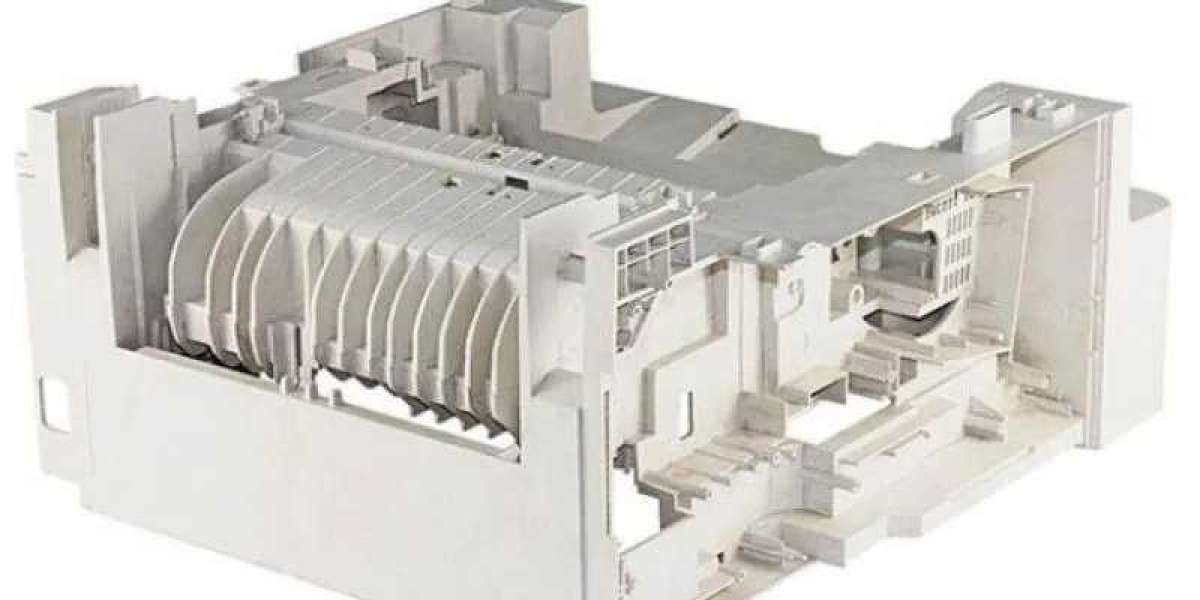

Composite printer plastic molding is a popular manufacturing process used to create a wide range of products. It involves the use of a mold to shape and form plastic materials into a desired shape. This process is widely used in various industries, including automotive, aerospace, and medical.

However, using composite printer plastic molds can be a challenging task, especially for beginners. There are several things to note when using these molds to ensure that the process is successful and the final product is of high quality. In this blog post, we will discuss some tips and tricks for successful composite printer plastic molding.

1. Choose the right material

The first thing to note when using composite printer plastic molds is to choose the right material. The material used for the mold should be able to withstand the high temperatures and pressures involved in the molding process. Common materials used for composite printer plastic molds include aluminum, steel, and epoxy.

Aluminum molds are lightweight and easy to machine, making them a popular choice for low-volume production. Steel molds, on the other hand, are more durable and can withstand higher temperatures and pressures, making them suitable for high-volume production. Epoxy molds are also a popular choice as they are easy to make and can be used for low-volume production.

2. Design the mold correctly

The design of the mold is crucial to the success of the molding process. The mold should be designed to ensure that the plastic material flows evenly and fills the mold cavity completely. The mold should also be designed to allow for easy removal of the final product.

When designing the mold, it is important to consider the shrinkage of the plastic material during the cooling process. The mold should be designed to compensate for this shrinkage to ensure that the final product is of the correct size and shape.

3. Use the right molding technique

There are several molding techniques used in composite printer plastic molding, including injection molding, compression molding, and transfer molding. Each technique has its advantages and disadvantages, and the choice of technique will depend on the specific requirements of the product being produced.

Injection molding is a popular technique used for high-volume production. It involves injecting molten plastic material into a mold cavity under high pressure. Compression molding, on the other hand, is used for low-volume production and involves compressing the plastic material into a mold cavity using a hydraulic press. Transfer molding is a hybrid technique that combines the advantages of injection molding and compression molding.

4. Control the temperature and pressure

Temperature and pressure are critical factors in composite printer plastic molding. The temperature of the mold should be controlled to ensure that the plastic material flows evenly and fills the mold cavity completely. The pressure of the molding machine should also be controlled to ensure that the plastic material is compressed evenly and the final product is of the correct size and shape.

It is important to note that different plastic materials have different temperature and pressure requirements. Therefore, it is essential to choose the right temperature and pressure settings for the specific plastic material being used.

5. Use release agents

Release agents are used to prevent the plastic material from sticking to the mold. They are applied to the mold surface before the plastic material is injected or compressed into the mold cavity. Release agents can be in the form of sprays, powders, or liquids.

It is important to choose the right release agent for the specific plastic material being used. Using the wrong release agent can result in poor surface finish and adhesion issues.

6. Post-processing

Post-processing is an essential step in composite printer plastic molding. It involves removing the final product from the mold and trimming any excess material. The final product may also require additional processing, such as painting, polishing, or assembly.

It is important to handle the final product carefully during post-processing to avoid damaging it. The final product should also be inspected to ensure that it meets the required specifications.

In conclusion, composite printer plastic molding is a complex process that requires careful consideration of several factors. Choosing the right material, designing the mold correctly, using the right molding technique, controlling the temperature and pressure, using release agents, and post-processing are all critical factors that can affect the success of the molding process. By following these tips and tricks, you can ensure that your composite printer plastic molding process is successful and the final product is of high quality.

Xuzhong Technology (Shenzhen) Co., Ltd. is located in Shenzhen, China, adjacent to Hong Kong. We are a company focusing on exporting mold business.We remain committed to delivering high quality, tight tolerance contract plastic injection molds.Provide high-quality mold products and high-quality services to global customers. We have high quality products, welcome to contact us!

https://www.xuzhongmold.com/Things-to-note-when-using-composite-printer-plastic-molds.html