Introduction

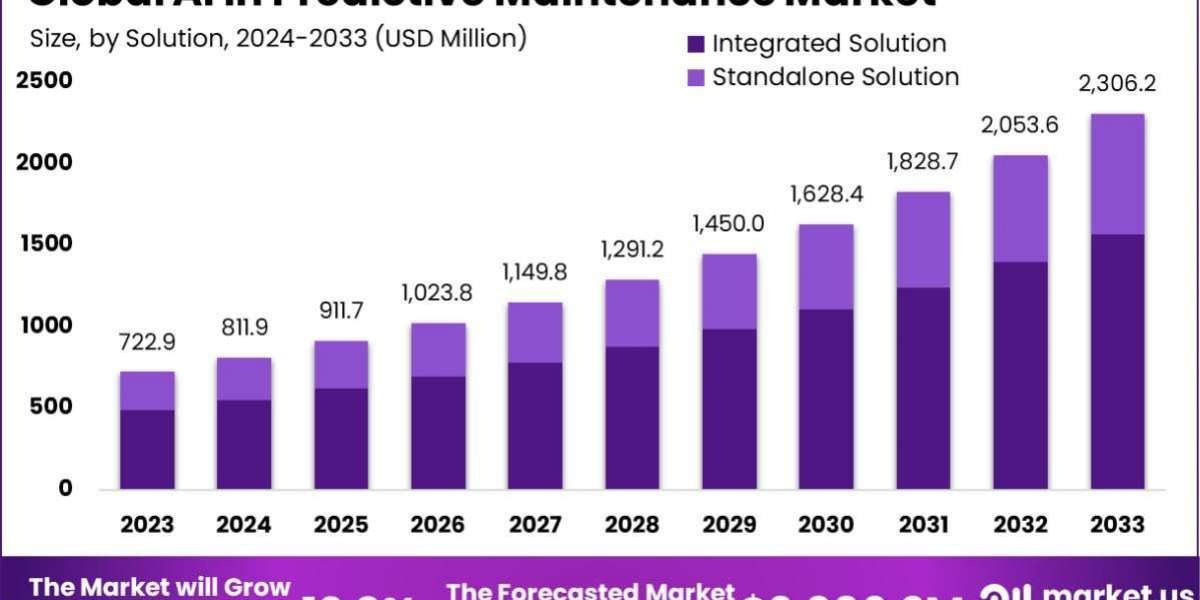

The Global AI in Predictive Maintenance Market size is expected to be worth around USD 2,306.2 Million By 2033, from USD 722.9 Million in 2023, growing at a CAGR of 12.3% during the forecast period from 2024 to 2033.

Read More - https://market.us/report/ai-in-predictive-maintenance-market/

The AI in Predictive Maintenance Market is rapidly transforming how industries manage their equipment and machinery. By utilizing advanced algorithms and machine learning, AI-driven predictive maintenance can foresee equipment failures before they occur. This proactive approach helps in minimizing downtime, reducing maintenance costs, and extending the lifespan of machines. Growth in this market is driven by increasing awareness of the cost-saving benefits of predictive maintenance, coupled with advancements in AI technologies that make these solutions more accessible and efficient.

However, the adoption of AI in predictive maintenance is not without challenges. One of the significant hurdles is the integration of AI systems with existing infrastructure, which can be complex and costly. Additionally, there is a need for skilled professionals who can manage and interpret AI-driven insights, creating a demand for specialized training and education. Despite these challenges, the opportunities in this market are vast. Industries ranging from manufacturing to healthcare can benefit from predictive maintenance, as it not only saves costs but also improves overall operational efficiency. As AI technology continues to evolve, the predictive maintenance market is poised for substantial growth.

Emerging Trends

Integration of IoT with AI: The combination of Internet of Things (IoT) devices with AI-driven predictive maintenance is becoming more prevalent. IoT sensors collect real-time data, which AI algorithms analyze to predict potential equipment failures, enabling more precise maintenance schedules.

Cloud-based Predictive Maintenance: The shift towards cloud computing allows companies to implement AI-driven predictive maintenance solutions without the need for extensive on-premise infrastructure. Cloud-based platforms offer scalability, real-time data processing, and easy integration with existing systems.

AI-Powered Diagnostics: AI is increasingly being used not just to predict when maintenance is needed, but also to diagnose the specific issues that may arise. This trend is helping companies to not only prevent failures but also address the root causes of potential problems more effectively.

Adoption of Digital Twins: Digital twins, which are virtual replicas of physical assets, are being used in conjunction with AI for predictive maintenance. This allows companies to simulate various scenarios and predict how changes in operations or environmental conditions could impact equipment performance.

Enhanced Data Analytics: The use of advanced data analytics in predictive maintenance is growing. AI algorithms can analyze vast amounts of data from multiple sources to provide more accurate predictions and actionable insights, helping companies make better-informed maintenance decisions.

Top Use Cases

Manufacturing Industry: In manufacturing, AI-driven predictive maintenance is used to monitor machinery and equipment, reducing unexpected breakdowns and optimizing production processes. This leads to significant cost savings and increased production efficiency.

Energy Sector: AI is employed to monitor and maintain critical infrastructure in the energy sector, such as turbines and pipelines. Predictive maintenance helps in preventing costly failures and ensures a consistent supply of energy.

Automotive Industry: In the automotive industry, AI-powered predictive maintenance is used to monitor the health of vehicles, predict potential failures, and schedule maintenance proactively. This helps in reducing downtime and improving vehicle reliability.

Healthcare Sector: Predictive maintenance is also making its way into the healthcare sector, where it is used to monitor medical equipment. By predicting potential equipment failures, hospitals can ensure that critical devices are always operational, thus improving patient care.

Aerospace Industry: In aerospace, predictive maintenance is crucial for ensuring the safety and reliability of aircraft. AI-driven systems monitor various components of an aircraft and predict when maintenance is required, helping to prevent in-flight failures.

Major Challenges

Data Quality and Availability: The effectiveness of AI-driven predictive maintenance relies heavily on the quality and availability of data. Poor-quality data or lack of sufficient data can lead to inaccurate predictions and ineffective maintenance strategies.

Integration with Existing Systems: Integrating AI-driven predictive maintenance solutions with existing legacy systems can be challenging. It often requires significant investment in new infrastructure and the retraining of personnel.

High Initial Costs: The initial cost of implementing AI-driven predictive maintenance systems can be high, which may be a barrier for small and medium-sized enterprises. This includes the cost of AI software, IoT sensors, and data storage solutions.

Lack of Skilled Professionals: There is a shortage of professionals with the skills required to manage and interpret the data generated by AI-driven predictive maintenance systems. This creates a gap between the potential of the technology and its practical implementation.

Privacy and Security Concerns: The collection and analysis of large amounts of data by AI systems raise concerns about data privacy and security. Companies need to ensure that they have robust security measures in place to protect sensitive information.

Market Opportunity

Expanding to New Industries: There is significant potential for AI-driven predictive maintenance to expand into new industries, such as retail and agriculture. As more industries recognize the benefits of predictive maintenance, the market is likely to see substantial growth.

Development of AI-Powered Tools: The development of more advanced AI-powered tools for predictive maintenance presents a major market opportunity. These tools can offer more accurate predictions and more detailed diagnostics, making them valuable to a wide range of industries.

Customization and Scalability: Offering customizable and scalable predictive maintenance solutions tailored to the specific needs of different industries can open up new market opportunities. Companies that can provide flexible solutions are likely to gain a competitive edge.

Partnerships and Collaborations: Collaborations between AI technology providers and industry-specific companies can lead to the development of innovative predictive maintenance solutions. Such partnerships can drive market growth by combining industry expertise with cutting-edge technology.

Focus on SMEs: There is an opportunity to develop cost-effective predictive maintenance solutions tailored to small and medium-sized enterprises (SMEs). By offering affordable and easy-to-implement solutions, companies can tap into this large and underserved market segment.

Conclusion

The AI in Predictive Maintenance Market is on the brink of significant growth as industries across the board recognize the value of AI-driven solutions in enhancing operational efficiency and reducing costs. While the market presents numerous opportunities, it also faces challenges such as high initial costs, data quality issues, and the need for skilled professionals. However, as AI technology continues to evolve and become more accessible, these challenges are likely to diminish, paving the way for broader adoption of predictive maintenance across various sectors.

In conclusion, the future of the AI in Predictive Maintenance Market looks promising. With continued advancements in AI and machine learning, along with growing awareness of the benefits of predictive maintenance, the market is expected to see sustained growth in the coming years. As companies continue to seek ways to improve efficiency and reduce costs, AI-driven predictive maintenance is set to play a crucial role in achieving these goals.