Pressure gauges are essential instruments used in various industries to measure and monitor pressure levels in different systems. One of the most common types of pressure gauges is the bourdon tube pressure gauge. This type of gauge is widely used because of its accuracy, reliability, and durability. However, like any other instrument, bourdon tube pressure gauges require regular maintenance to ensure their optimal performance and longevity.

In this blog post, we will discuss the maintenance of aluminum alloy bourdon tube pressure gauges. We will cover the different parts of the gauge, the tools required for maintenance, and the steps involved in maintaining the gauge.

Parts of Aluminum Alloy Bourdon Tube Pressure Gauge

Before we dive into the maintenance process, let's first understand the different parts of an aluminum alloy bourdon tube pressure gauge. The gauge consists of the following parts:

1. Bourdon Tube: This is the most critical part of the gauge. It is a curved tube made of aluminum alloy that expands or contracts when subjected to pressure changes. The movement of the bourdon tube is transmitted to the pointer, which indicates the pressure reading on the gauge.

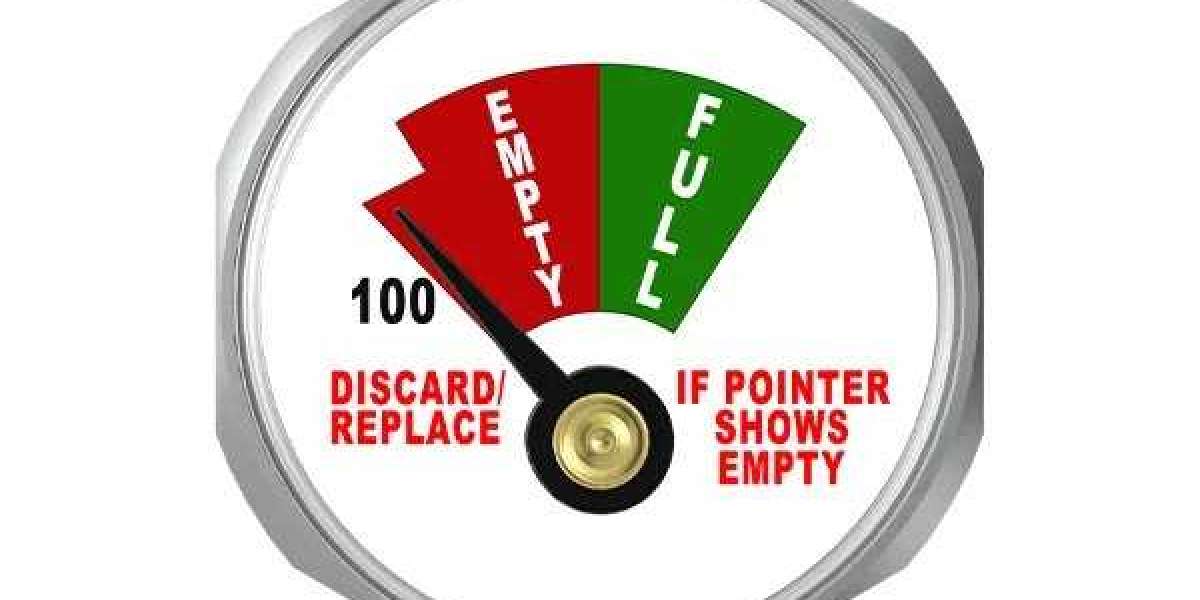

2. Pointer: The pointer is attached to the bourdon tube and moves along the gauge's dial to indicate the pressure reading.

3. Dial: The dial is the face of the gauge that displays the pressure readings. It is usually marked with different pressure units, such as psi, bar, or kPa.

4. Case: The case is the outer covering of the gauge that protects the internal parts from damage. It is usually made of aluminum alloy or stainless steel.

Tools Required for Maintenance

To maintain an aluminum alloy bourdon tube pressure gauge, you will need the following tools:

1. Soft-bristled brush: This is used to remove dust and debris from the gauge's dial and case.

2. Cleaning solution: You can use a mild soap solution or a specialized cleaning solution designed for pressure gauges.

3. Soft cloth: This is used to wipe the gauge's dial and case after cleaning.

4. Lubricant: A silicone-based lubricant is recommended for lubricating the bourdon tube and other moving parts of the gauge.

5. Calibration equipment: To ensure the gauge's accuracy, you will need calibration equipment, such as a deadweight tester or a pressure comparator.

Steps for Maintaining Aluminum Alloy Bourdon Tube Pressure Gauge

Now that you have the necessary tools let's dive into the maintenance process. Here are the steps involved in maintaining an aluminum alloy bourdon tube pressure gauge:

Step 1: Turn off the system

Before you start the maintenance process, ensure that the system where the gauge is installed is turned off. This will prevent any pressure fluctuations that may damage the gauge.

Step 2: Remove the gauge from the system

Next, remove the gauge from the system. You can do this by unscrewing the gauge from the system's connection point. Be careful not to damage the gauge's threads or the system's connection point.

Step 3: Clean the gauge's dial and case

Using a soft-bristled brush, remove any dust or debris from the gauge's dial and case. You can also use a cleaning solution to remove any stubborn dirt or stains. Be careful not to use a cleaning solution that may damage the gauge's dial or case.

Step 4: Lubricate the bourdon tube and other moving parts

Apply a small amount of silicone-based lubricant to the bourdon tube and other moving parts of the gauge. This will ensure that the gauge's movement is smooth and accurate.

Step 5: Reinstall the gauge

Once you have cleaned and lubricated the gauge, reinstall it back into the system. Ensure that the gauge is securely fastened to the system's connection point.

Step 6: Calibrate the gauge

To ensure the gauge's accuracy, you will need to calibrate it using calibration equipment, such as a deadweight tester or a pressure comparator. Follow the manufacturer's instructions for calibrating the gauge.

Step 7: Record the calibration results

After calibrating the gauge, record the calibration results. This will help you track the gauge's performance over time and identify any issues that may arise.

Step 8: Schedule regular maintenance

Regular maintenance is essential to ensure the optimal performance and longevity of the gauge. Schedule regular maintenance, such as cleaning and lubrication, to keep the gauge in good condition.

Conclusion

Maintaining an aluminum alloy bourdon tube pressure gauge is essential to ensure its accuracy, reliability, and longevity. By following the steps outlined in this blog post, you can keep your gauge in good condition and avoid costly repairs or replacements. Remember to schedule regular maintenance and record the calibration results to track the gauge's performance over time. With proper maintenance, your aluminum alloy bourdon tube pressure gauge will provide accurate and reliable pressure readings for years to come.

Established since the year of 1985, Safestar Co., Ltd. has been dedicating in producing and researching the pressure gauges for fire extinguishers. Our products have got EN3-7 approval, Spanish AENOR certificate and UL approval. Striving for more than 40 years, now we have 230 employees and occupy an area of 5 hectares and building area of 30000 ㎡, possesses more than 120 sets of digital control machines , more than ten of automatic helium gas leaking test machines, more than twenty sets of automatic imaging calibration equipment and automatic production lines. We will provide you with high-quality products and considerate services. Welcome to inquire.

https://www.safestar.com.cn/Maintenance-of-aluminum-alloy-bourdon-tube-pressure-gauge.html