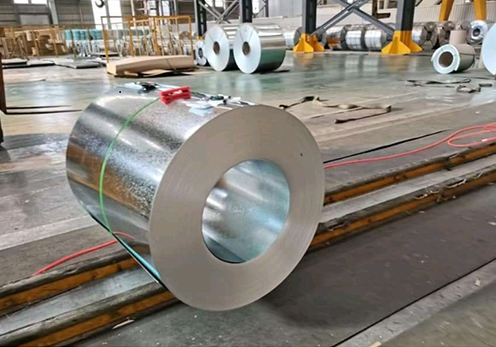

Hot-dip galvanized steel coils have become a popular choice in various industries due to their exceptional properties and wide-ranging applications. Understanding the unique characteristics of these coils is crucial for making informed decisions when it comes to selecting the right material for your projects. In this article, we will delve into the properties of hot-dip galvanized steel coils, shedding light on their strength, durability, corrosion resistance, and more. Let's explore!

I. Strength and Structural Integrity

Hot-dip galvanized steel coils exhibit excellent strength, making them suitable for demanding structural applications. The galvanization process involves immersing the steel coils into a bath of molten zinc, forming a metallurgical bond between the zinc and the steel. This bond enhances the overall strength of the steel, providing structural integrity and ensuring the coils can withstand heavy loads and external forces.

II. Corrosion Resistance

One of the most remarkable properties of hot-dip galvanized steel coils is their exceptional corrosion resistance. The zinc coating acts as a protective barrier, shielding the underlying steel from corrosion caused by moisture, chemicals, and other corrosive elements. This makes galvanized steel coils highly suitable for applications where exposure to harsh environments, including marine and industrial settings, is expected.

III. Longevity and Durability

Hot-dip galvanized steel coils offer unparalleled durability and longevity. The thick layer of zinc alloy formed during the galvanization process provides a robust protective coating that can withstand the test of time. Galvanized steel coils can last up to several decades without significant degradation, reducing maintenance costs and ensuring the longevity of the structures they are used in.

IV. Aesthetic Appeal

Apart from their functional properties, hot-dip galvanized steel coils also offer an attractive appearance. The zinc coating provides a distinctive, spangled pattern on the surface of the coils, adding visual appeal to various architectural and decorative applications. The bright, metallic finish of galvanized steel coils can enhance the aesthetic value of structures, making them a popular choice in industries such as construction and design.

V. Formability and Workability

Hot-dip galvanized steel coils possess excellent formability and workability, allowing for easy shaping and fabrication. The galvanization process does not significantly affect the mechanical properties of the steel, enabling it to be bent, formed, and welded without compromising its strength. This versatility makes galvanized steel coils suitable for a wide range of manufacturing processes and applications.

VI. Heat Resistance

Hot-dip galvanized steel coils exhibit remarkable heat resistance, making them ideal for applications that involve exposure to high temperatures. The zinc coating on the steel acts as a barrier, protecting the underlying material from heat-induced damage and maintaining its structural integrity. This property makes galvanized steel coils suitable for applications such as automotive components, HVAC systems, and industrial equipment that operate in elevated temperature environments.

VII. Sustainability and Recyclability

Hot-dip galvanized steel coils are an environmentally friendly choice due to their sustainability and recyclability. The galvanizing process consumes fewer resources compared to other coating methods, reducing its carbon footprint. Additionally, galvanized steel is fully recyclable, allowing for the recovery and reuse of the material at the end of its life cycle. This sustainability aspect makes galvanized steel coils a preferred choice for eco-conscious industries and projects.

VIII. Cost-effectiveness

Hot-dip galvanized steel coils offer a cost-effective solution for various applications. While the initial cost of galvanizing may be slightly higher compared to other coating methods, the long-term benefits outweigh the upfront investment. The extended lifespan, low maintenance requirements, and reduced need for replacements make galvanized steel coils a financially viable option in the long run.

IX. Applications of Hot-Dip Galvanized Steel Coils

Hot-dip galvanized steel coils find application in a wide range of industries and sectors. Some common uses include:

Construction and infrastructure: Galvanized steel coils are widely employed in the construction of buildings, bridges, and highways due to their strength, durability, and corrosion resistance.

Automotive industry: Galvanized steel coils are used in the manufacturing of automotive components, such as frames, chassis, and body panels, to provide both structural integrity and protection against rust.

Electrical industry: The excellent electrical conductivity of galvanized steel coils makes them suitable for electrical applications, including conduits, electrical cabinets, and enclosures.

Agricultural equipment: Galvanized steel coils are used in the fabrication of agricultural machinery and equipment due to their resistance to corrosion caused by fertilizers, chemicals, and outdoor exposure.

Manufacturing and fabrication: Galvanized steel coils are utilized in various manufacturing processes, including metal stamping, roll forming, and fabrication of pipes, tubes, and profiles.

Conclusion

Hot-dip galvanized steel coils possess a unique combination of properties that make them an ideal choice for a wide range of applications. From their exceptional strength and corrosion resistance to their longevity, formability, and sustainability, galvanized steel coils offer numerous advantages. Whether in constructionprojects, automotive manufacturing, or electrical applications, the properties of hot-dip galvanized steel coils ensure reliable performance and long-lasting durability.

Shandong Aofeng Metal Material CO., LTD.was established in 2011, located in Liaocheng-one of the biggest cold rolled stainless steel production bases. Aofeng is specializing in processing cold rolle stainless steel coils and sheets.

Welcome to contact us,if you are interested in our products.

Email:john@sdafjs.com