Walking beam processing service is a game-changer for manufacturers looking to streamline their production process. This innovative technology allows for the efficient movement of materials through various stages of production, resulting in increased productivity and reduced costs. With the ability to handle heavy loads and high temperatures, walking beam processing service is ideal for a wide range of industries, including automotive, aerospace, and construction. In this article, we will explore the benefits of walking beam processing service and how it can help your business achieve greater success.

What is walking beam processing?

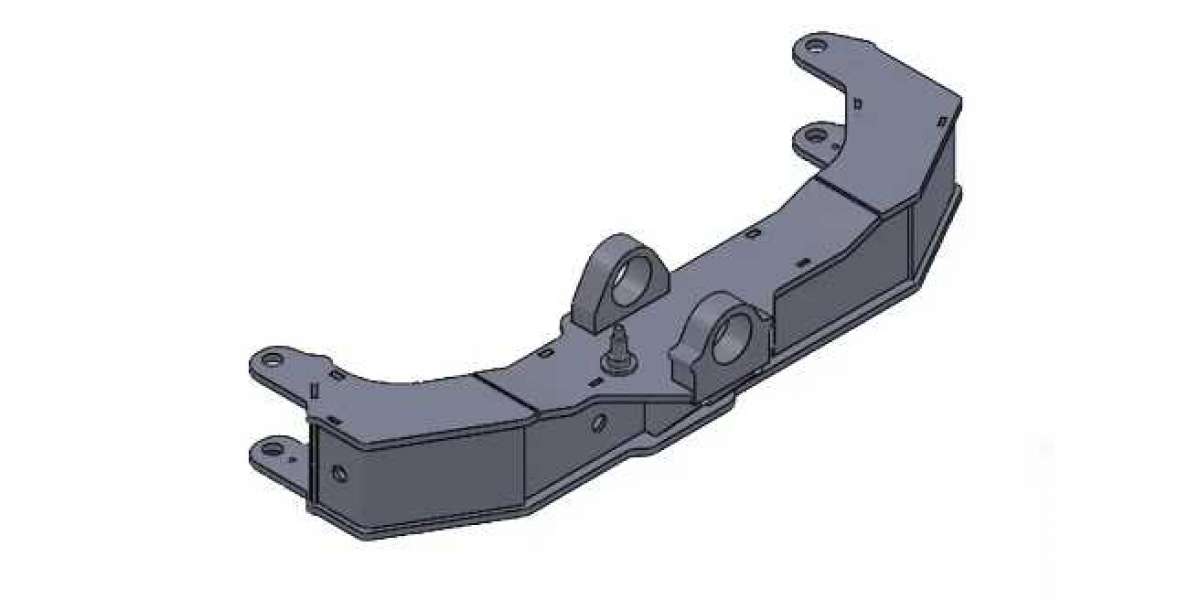

Walking beam processing is a specialized manufacturing technique that involves the use of a walking beam mechanism to transport and process materials or products along a production line. A walking beam, also known as a reciprocating conveyor, consists of multiple interconnected beams that move synchronously.

At its core, walking beam machining is about delivering exceptional versatility and precision. This mechanism allows the controlled movement of material from one work station to another, ensuring seamless transitions between the various stages of the production process. This eliminates the need for manual processing or other tedious methods, ultimately saving time and reducing costs.

One of the key advantages of walking beam machining is the ability to easily handle heavy loads. The system's design and construction make it ideal for transporting bulky items or components through different workstations without compromising safety or efficiency.

Additionally, custom walking beam systems can be customized to meet specific requirements based on the nature of your industry or product. The technology can be adapted to different applications, from assembly lines in automotive manufacturing to metal fabrication processes.

Walking beam processing is an innovative solution that streamlines production processes by automating material transport and processing tasks. Its versatility, precision and adaptability make it a valuable tool for businesses seeking to optimize operations while increasing productivity and cost efficiency.

Advantages of walking beam processing

Walking beam machining offers several advantages, making it an ideal solution for streamlining production processes.

One of the main advantages of walking beam processing is its versatility. The process can be customized to meet specific requirements and adapt to a variety of materials and products. Whether you need to heat treat, coat or clean your parts, a walking beam system can meet your needs.

Another benefit is its high degree of automation. With this processing service, you can automate various steps in your production line, reducing manual labor and increasing efficiency. The walking beam system allows parts to move continuously through different stages of the process without interruption or delay.

Additionally, walking beam machining is known for its precision and consistency. Controlled movement ensures every part is treated equally and meets tight tolerances. This minimizes quality variations and improves overall product performance.

In addition, this treatment method provides excellent load stability during transportation within the system. It prevents damage to precision components by minimizing the vibration or shock associated with other handling methods.

Another benefit worth mentioning is the potential cost savings from implementing walking beam handling services into your operation. By optimizing workflows and reducing downtime between processes, companies can achieve higher productivity levels while minimizing waste and maximizing resource utilization.

In summary, walking beam machining offers several advantages such as versatility, automation capabilities, safety, and increased efficiency, making it an attractive option for businesses looking to streamline their production processes.

Different Applications of Walking Beam Processing Service

Walking beam processing service has a wide range of applications across various industries. It is a versatile technique that can be utilized in different manufacturing processes to streamline production and improve efficiency.

One application of walking beam processing service is in the steel industry. The walking beam furnace, also known as pusher furnace, is commonly used for heat treating steel components. This process involves moving the workpiece through a series of heating and cooling zones using a continuous conveyor system. The walking beam mechanism ensures precise control over the speed and position of each workpiece, resulting in uniform heat treatment and improved product quality.

Another application of walking beam processing service is in the automotive industry. Many automobile manufacturers utilize this technique for their assembly lines, particularly for welding operations. The walking beam system allows for smooth movement and positioning of car bodies or chassis during welding processes, ensuring accurate alignment and reducing errors.

Furthermore, the woodworking industry can benefit from walking beam processing service as well. By incorporating this technology into their production line, woodworking companies can improve precision cutting and shaping operations. The walking beams ensure consistent movement and support throughout the cutting process, enhancing accuracy while minimizing waste.

In addition to these industries, other sectors such as aerospace, energy generation, and appliance manufacturing also find value in utilizing custom walking beam systems tailored to their specific needs.

Conclusion

In today's fast-paced manufacturing industry, efficiency and productivity are key factors for success. Walking beam processing service is a reliable solution that can streamline your production process and help you stay ahead of the competition.

With its ability to handle heavy loads and provide precise movement, walking beam systems offer numerous advantages. They eliminate the need for manual handling, reduce downtime, increase throughput, improve safety, and ensure consistent quality output.

Whether you require custom walking beams for material handling or specialized walking beam processing services for heat treatment or surface finishing applications, partnering with an experienced provider can enhance your overall operational efficiency.

By leveraging the expertise of professionals in the field of walking beam technology, you can optimize your production line and achieve higher levels of productivity while maintaining exceptional product quality.

So why wait? Explore the possibilities that walking beam processing service has to offer and take your manufacturing process to new heights. By incorporating this innovative technology into your operations, you'll be able to meet increasing demands effectively while minimizing costs and maximizing profitability.