Composite printer metal molds are an essential component of the printing industry. They are used to create high-quality prints on a variety of materials, including paper, plastic, and metal. However, like any other equipment, these molds require regular maintenance and repair to ensure their longevity and optimal performance. In this blog post, we will discuss the maintenance and repair of composite printer metal molds in detail.

What is a Composite Printer Metal Mold?

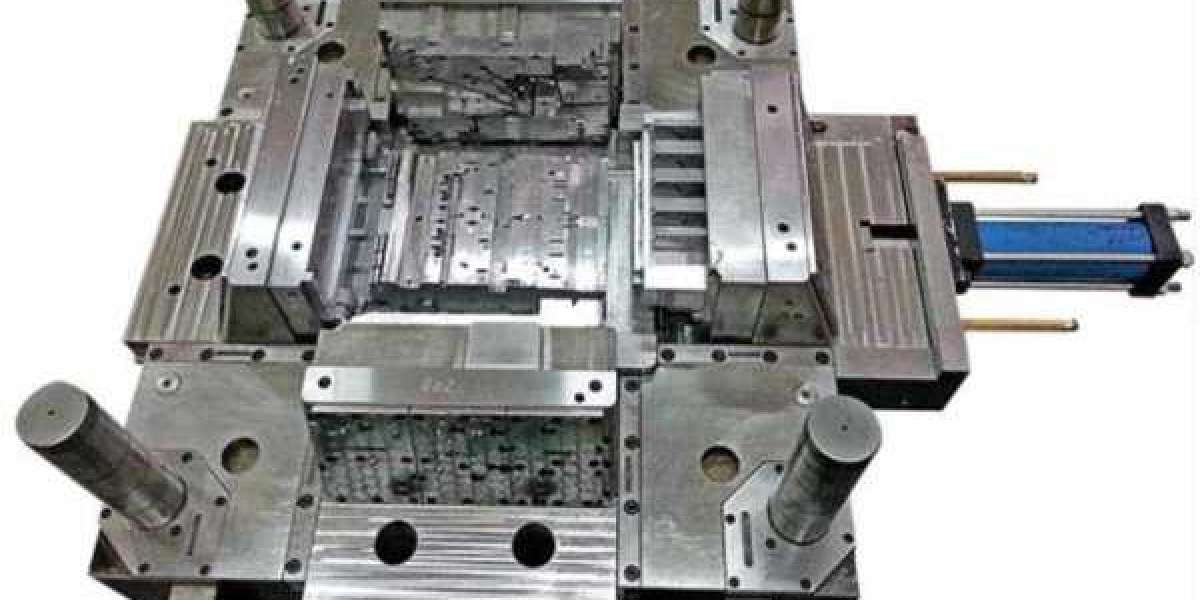

A composite printer metal mold is a tool used in the printing industry to create high-quality prints. It is made up of a combination of materials, including metal, plastic, and composite materials. The mold is designed to create a specific shape or design that is then used to print images or text onto a variety of materials.

Maintenance of Composite Printer Metal Mold

Regular maintenance of composite printer metal molds is essential to ensure their longevity and optimal performance. Here are some tips for maintaining your composite printer metal mold:

1. Clean the Mold Regularly

Cleaning the mold regularly is essential to prevent the buildup of dirt, dust, and other debris that can affect the quality of the prints. Use a soft cloth or brush to remove any debris from the mold's surface. Avoid using harsh chemicals or abrasive materials that can damage the mold.

2. Lubricate the Mold

Lubricating the mold is essential to ensure that it operates smoothly and efficiently. Apply a small amount of lubricant to the mold's moving parts, such as the hinges and springs. Be sure to use a lubricant that is compatible with the mold's materials.

3. Inspect the Mold for Damage

Regularly inspecting the mold for damage is essential to prevent any issues that can affect the quality of the prints. Check for any cracks, dents, or other damage that can affect the mold's performance. If you notice any damage, repair it immediately.

4. Store the Mold Properly

Storing the mold properly is essential to prevent any damage that can affect its performance. Store the mold in a dry, cool place away from direct sunlight and moisture. Avoid storing the mold in an area with extreme temperatures or humidity.

Repair of Composite Printer Metal Mold

Despite regular maintenance, composite printer metal molds can still experience damage or wear and tear over time. Here are some tips for repairing your composite printer metal mold:

1. Identify the Problem

Identifying the problem is the first step in repairing your composite printer metal mold. Check for any cracks, dents, or other damage that can affect the mold's performance. If you are unsure of the problem, consult the manufacturer's instructions or a professional technician.

2. Clean the Mold

Before repairing the mold, clean it thoroughly to remove any debris or dirt that can affect the repair process. Use a soft cloth or brush to remove any debris from the mold's surface.

3. Repair the Mold

Depending on the type and severity of the damage, there are several methods for repairing composite printer metal molds. Here are some common repair methods:

- Welding: Welding is a common method for repairing metal molds. It involves melting the metal and fusing it back together. This method is best for repairing cracks or breaks in the mold.

- Bonding: Bonding involves using an adhesive to bond the broken pieces of the mold back together. This method is best for repairing small cracks or breaks in the mold.

- Machining: Machining involves using a machine to remove the damaged area of the mold and replace it with a new piece. This method is best for repairing large areas of damage or wear and tear.

4. Test the Mold

After repairing the mold, test it to ensure that it is functioning properly. Print a test image or text to check the quality of the print. If the mold is not functioning properly, repeat the repair process or consult a professional technician.

Conclusion

Composite printer metal molds are an essential component of the printing industry. Regular maintenance and repair of these molds are essential to ensure their longevity and optimal performance. By following the tips outlined in this blog post, you can maintain and repair your composite printer metal mold effectively. Remember to always consult the manufacturer's instructions or a professional technician if you are unsure of how to maintain or repair your mold.

Xuzhong is a professional composite printer metal mold supplier. If you want to buy this product, please come to us for consultation. We will provide you with considerate services and high-quality products.

https://www.xuzhongmold.com/Maintenance-and-repair-of-composite-printer-metal-mold.html