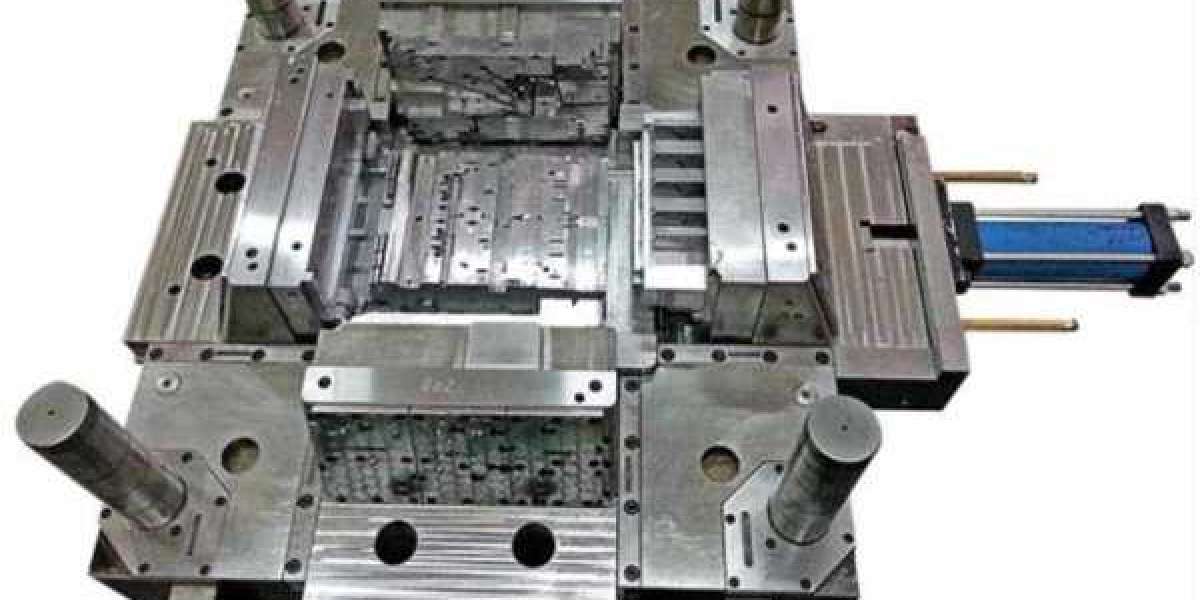

In the rapidly evolving world of manufacturing, the quest for cost-effective and efficient production methods is a constant endeavor. One groundbreaking innovation that has gained significant attention is the application of composite printer metal molds. These cutting-edge molds combine the advantages of composite materials with the precision and durability of metal, offering a range of benefits that revolutionize various industries. In this blog post, we will explore the diverse applications of cost-effective composite printer metal molds and delve into the ways they are transforming manufacturing processes.

1. Automotive Industry:

The automotive industry is one of the primary beneficiaries of composite printer metal molds. Traditionally, metal molds have been used for manufacturing automotive parts, but they often come with high costs and long lead times. Composite printer metal molds, on the other hand, offer a cost-effective alternative without compromising on quality or precision. These molds can be produced quickly and at a fraction of the cost, enabling manufacturers to streamline their production cycles and reduce overall expenses. From interior components to exterior body parts, composite printer metal molds are reshaping the automotive manufacturing landscape.

2. Aerospace Sector:

The aerospace sector demands the utmost precision and reliability in its manufacturing processes. Composite printer metal molds have emerged as a game-changer in this industry, enabling the production of complex and lightweight components with exceptional accuracy. By leveraging the benefits of composite materials, such as high strength-to-weight ratio and resistance to corrosion, aerospace manufacturers can create intricate parts that meet stringent performance requirements. Moreover, the cost-effectiveness of composite printer metal molds allows for rapid prototyping and iterative design improvements, facilitating innovation and enhancing overall efficiency.

3. Consumer Electronics:

The consumer electronics industry is characterized by its fast-paced nature and constant demand for innovation. Composite printer metal molds offer a competitive advantage in this sector by enabling the production of intricate and customized components with reduced lead times. From smartphone casings to wearable devices, these molds allow manufacturers to experiment with new designs and functionalities without incurring exorbitant costs. Additionally, the lightweight nature of composite materials contributes to the overall portability and user-friendliness of consumer electronic products.

4. Medical Equipment:

The medical equipment industry requires precision, reliability, and cost-effectiveness in the production of devices and components. Composite printer metal molds have found significant applications in this sector, enabling the manufacturing of intricate medical equipment parts with high accuracy. These molds facilitate the production of custom-made implants, prosthetics, and surgical instruments, catering to the unique needs of patients. The cost-effectiveness of composite printer metal molds also plays a crucial role in reducing healthcare expenses, making advanced medical equipment more accessible to a wider population.

5. Industrial Manufacturing:

In industrial manufacturing, composite printer metal molds offer numerous advantages, particularly in the production of large-scale components and machinery. The lightweight nature of composite materials reduces the overall weight of the final products, leading to improved energy efficiency and reduced transportation costs. Moreover, the cost-effective nature of composite printer metal molds allows for the production of complex and intricate parts, enhancing the performance and functionality of industrial machinery. From turbines to heavy machinery components, these molds are transforming the landscape of industrial manufacturing.

Conclusion:

The application of cost-effective composite printer metal molds has revolutionized manufacturing processes across various industries. From automotive and aerospace to consumer electronics, medical equipment, and industrial manufacturing, these molds offer a range of benefits that drive innovation, reduce costs, and enhance overall efficiency. By combining the advantages of composite materials with the precision and durability of metal, manufacturers can achieve remarkable results in terms of product quality, customization, and time-to-market. As technology continues to advance, the application of composite printer metal molds is poised to reshape the future of manufacturing, paving the way for a more sustainable and cost-effective industry.

Xuzhong is a professional injection mold supplier. If you want to buy cost-effective composite printer metal mold, please come to us for consultation. We will provide you with considerate services and high-quality products.

https://www.xuzhongmold.com/Application-of-cost-effective-composite-printer-metal-mold.html