In the rapidly evolving landscape of battery technology, particularly in lithium-ion batteries, the production process has become increasingly sophisticated. One critical piece of equipment that plays a vital role in ensuring the quality and efficiency of pouch cell manufacturing is the Auto Degas Machine. At Mikrouna, we specialize in advanced manufacturing solutions, including state-of-the-art auto degas machines designed specifically for pouch cell production. This blog will delve into the importance of auto degas machines, their functionality, and their applications in the production of high-quality pouch cells.

The Importance of Degassing in Pouch Cell Production

Degassing is a crucial step in the manufacturing of lithium-ion pouch cells. During the production process, gases can become trapped within the electrolyte or the cell structure. If not removed, these gases can lead to several issues:

- Reduced Battery Performance: Trapped gases can hinder ion movement within the battery, reducing overall performance and efficiency.

- Safety Hazards: Accumulated gases can lead to pressure buildup, increasing the risk of leaks or even explosions.

- Decreased Lifespan: The presence of gases can accelerate degradation processes within the battery, shortening its lifespan.

An auto degas machine effectively removes these gases, ensuring that the pouch cells produced are safe, efficient, and long-lasting.

How Auto Degas Machines Work

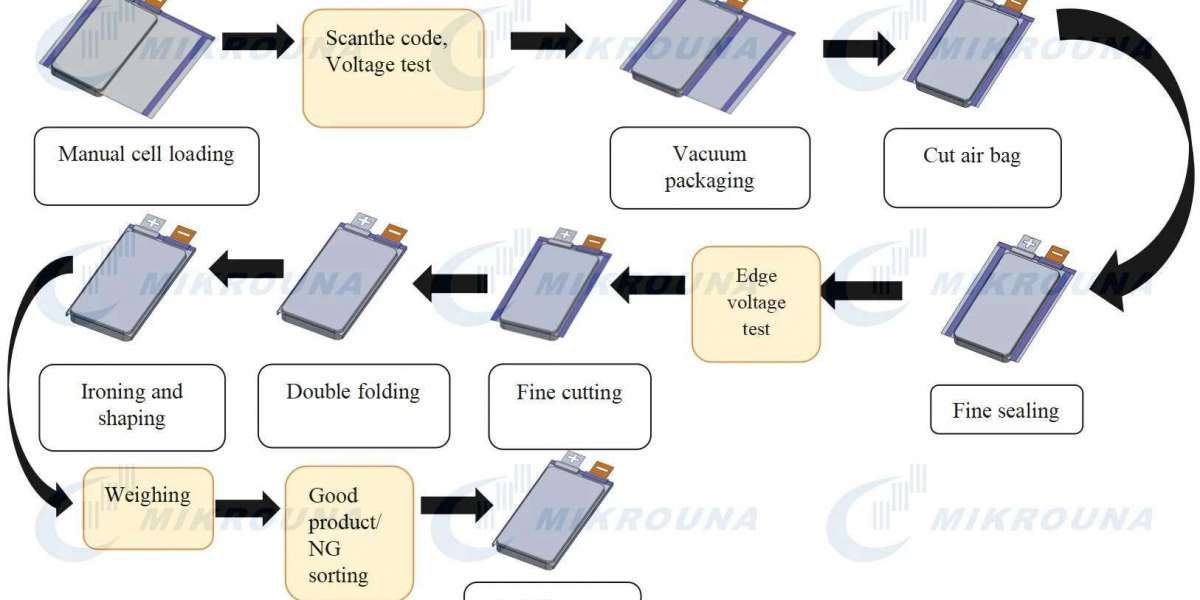

An auto degas machine employs a series of mechanisms to ensure thorough degassing of pouch cells:

1. Feeding Mechanism: The machine is equipped with a positioning groove for easy loading and unloading of battery cells. It incorporates sensors to detect whether products are present at each stage. Voltage testing is performed using flat-head brass probes, ensuring that only qualified cells proceed through the production line.

2. Battery Positioning Mechanism: This mechanism adjusts to secure the battery in place during processing. It prevents compression while allowing for necessary movements during degassing.

3. Vacuum Sealing Mechanism: The heart of the degassing process involves creating a vacuum environment. The machine uses a turntable structure with multiple stations to efficiently process several cells simultaneously. This setup significantly reduces production time while maintaining high standards.

4. Fine Sealing Mechanism: After degassing, it is essential to seal the cells properly to maintain their integrity. The fine sealing mechanism ensures that each cell is sealed under optimal conditions, preventing any potential leaks.

5. Cutting Air Bag Mechanism: This mechanism cuts off excess packaging material after sealing, ensuring that only the necessary components remain for optimal performance.

6. Edge Voltage Test Mechanism: To ensure safety and functionality, this mechanism tests the voltage at the edges of each cell before they are finalized for packaging.

7. Cutting and Folding Mechanism: This part of the machine handles precise cutting and folding of edges to ensure a perfect fit and finish for each pouch cell.

8. Weighing Mechanism: After all processes are complete, each cell is weighed to ensure it meets specified standards before moving on to sorting and packaging.

9. Interactive Control System: The entire process is monitored via an interactive touch screen that allows operators to track progress and make adjustments as needed.

10. Robust Frame and Dust-Proof Cover: The machine's design includes a sturdy frame for stability during operation and a dust-proof cover to protect sensitive components from contamination.

Applications in Pouch Cell Production

The versatility of auto degas machines makes them essential in various applications:

- Flexible Packaging Lithium-Ion Batteries: Ideal for producing batteries used in electric vehicles, consumer electronics, and renewable energy storage systems.

- High-Power Applications: Suitable for batteries requiring high discharge rates, such as those used in power tools or electric vehicles.

- Medical Devices: Ensures that batteries used in medical devices are safe and reliable by removing potential hazards associated with gas buildup.

Benefits of Using Auto Degas Machines

Investing in an auto degas machine offers numerous advantages:

- Improved Battery Quality: By ensuring thorough degassing, these machines enhance overall battery performance and reliability.

- Increased Efficiency: Automated processes reduce manual labor and speed up production times.

- Enhanced Safety: By minimizing risks associated with gas accumulation, manufacturers can produce safer batteries.

- Customization Options: Mikrouna’s auto degas machines can be tailored to meet specific production requirements, making them suitable for various applications.

Conclusion

As the demand for high-quality lithium-ion batteries continues to grow, so does the importance of sophisticated manufacturing equipment like auto degas machines. At Mikrouna, we are dedicated to providing cutting-edge solutions that enhance battery production efficiency while ensuring safety and reliability. Our auto degas machines are designed with advanced technology to meet the evolving needs of the industry.

If you’re interested in learning more about our auto degas machines or how they can benefit your pouch cell production process, please reach out! Together, we can drive innovation in battery technology and contribute to a more sustainable future.