The beauty industry is continuously evolving mop making machine, driven by innovation and changing consumer demands. Among the lesser-known yet vital tools in this sector are mops, which play an essential role in maintaining cleanliness and hygiene in salons, spas, and beauty establishments. The advent of mop making machines has significantly transformed the production of these essential tools, leading to enhanced quality, efficiency, and sustainability. This article explores the profound impact of mop making machines on the beauty industry, highlighting their features, benefits, and future prospects.

Understanding MOP Making Machines

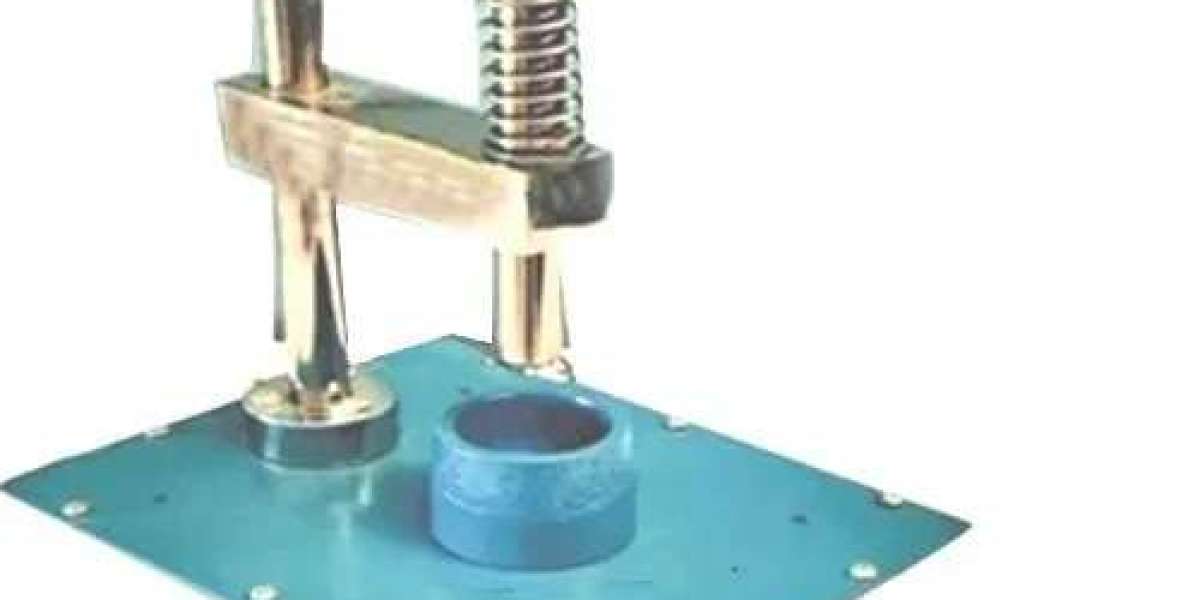

Mop making machines are specialized equipment designed to manufacture various types of mops, including traditional cotton mops, microfiber mops, and even disposable options. These machines automate the production process, allowing for greater consistency and quality in the final product.

Key Features of Modern MOP Making Machines

Automated Production Lines

Modern mop making machines are equipped with automated production lines that streamline the manufacturing process. This automation reduces manual labor and minimizes human error, ensuring each mop meets the desired quality standards.

Precision Engineering

Advanced technologies, such as CNC (Computer Numerical Control), allow for precise cutting and assembly of mop components. This precision is crucial in creating effective cleaning tools that perform reliably.

Customization Capabilities

Many machines offer customization options, enabling manufacturers to produce a wide variety of mop types and sizes. This flexibility allows businesses to cater to specific customer needs and preferences.

Eco-Friendly Production

Innovations in mop making technology have led to more sustainable manufacturing practices. Machines designed to utilize biodegradable materials and reduce waste align with the beauty industry’s growing emphasis on sustainability.

High-Speed Production

With the ability to produce large quantities of mops in a short period, these machines help manufacturers meet increasing demand without compromising quality.

Benefits of MOP Making Machines in the Beauty Industry

The introduction of mop making machines has brought numerous advantages to the beauty sector:

Enhanced Efficiency and Productivity

Automated mop production significantly increases efficiency, allowing manufacturers to produce mops at a faster rate. This enhanced productivity helps businesses respond to market demands promptly and effectively.

Improved Quality Control

Modern machines come equipped with advanced quality control systems that monitor production in real-time. This ensures that only the highest quality mops are produced, reducing defects and enhancing overall customer satisfaction.

Cost-Effectiveness

By automating production processes, manufacturers can reduce labor costs and operational expenses. These savings can be passed on to consumers, making high-quality mops more affordable for salons and beauty businesses.

Rapid Adaptation to Trends

The beauty industry is known for its ever-changing trends. Mop making machines enable manufacturers to quickly adapt their production lines to create new mop styles or materials in response to consumer preferences, providing a competitive edge in the market.

The Future of MOP Making Machines in the Beauty Industry

As technology advances, the future of mop making machines holds exciting possibilities:

Integration of Smart Technology

The rise of smart manufacturing will likely see the incorporation of IoT (Internet of Things) technologies in mop making machines. This integration will allow for real-time monitoring and data analysis, optimizing production processes and reducing downtime.

Sustainability as a Priority

As consumers become more environmentally conscious, the demand for sustainable products will continue to grow. Future mop making machines will likely focus on eco-friendly materials and processes, helping manufacturers meet this demand and reduce their environmental footprint.

Personalized Cleaning Solutions

The trend towards personalization is not limited to beauty products. Future mop making machine may offer enhanced customization features, allowing businesses to produce specialized mops for unique cleaning applications within the beauty industry.

Follow Us On More Links:-

Follow Us On Facebook:- https://www.facebook.com/people/Habito-Designs/100064230276942/

Follow Us On Instagram:- https://www.instagram.com/habitodesigns/

Follow Us On Linkedin:- https://www.linkedin.com/company/habito-designs

Address:- 20 Silistria Cl, Knaphill, Woking GU21 2TL, United Kingdom

Email Us:- enquiries@habitodesigns.com

Contact Us:- 07726 313 993