In today’s fast-paced manufacturing and product development world, speed and precision are key. Rapid tooling has emerged as a powerful technique for accelerating the prototype development process. It allows designers and engineers to create high-quality, functional prototypes in a fraction of the time and cost of traditional tooling methods. By reducing lead times and enabling quick iterations, rapid tooling helps businesses test, refine, and bring their products to market faster than ever before.

What is Rapid Tooling?

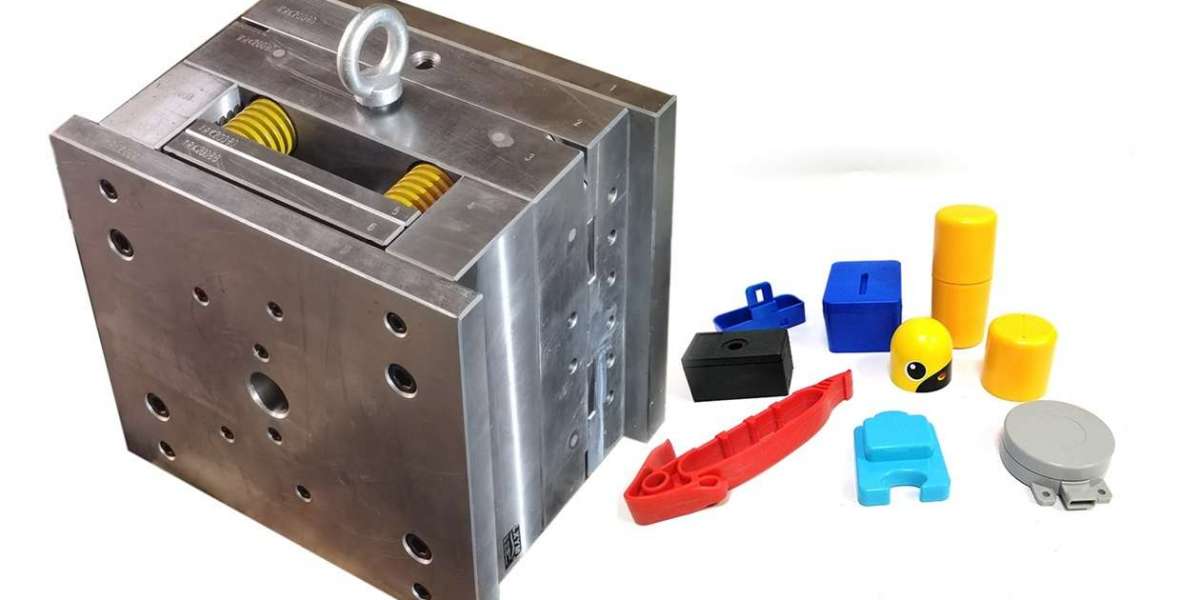

Rapid tooling involves the use of advanced manufacturing technologies, such as 3D printing, CNC machining, and injection molding, to quickly produce tooling for prototypes. Unlike traditional tooling, which can take weeks or even months to complete, rapid tooling allows designers to create functional molds, jigs, and other tools in just days, helping to significantly shorten the product development cycle.

Key Benefits of Using Rapid Tooling for Prototype Development

Faster Time to Market

One of the biggest advantages of rapid tooling is the ability to accelerate the product development timeline. Traditional tooling methods often require lengthy design, testing, and production phases. With rapid tooling, prototypes can be produced quickly, allowing teams to test and refine their designs faster. This quick turnaround means businesses can bring products to market much sooner, gaining a competitive edge.

Cost Efficiency

Traditional tooling processes can be costly, especially for low-volume production runs. Rapid tooling reduces these costs by eliminating the need for expensive molds and tools that may only be used for a small batch of prototypes. Since rapid tooling often relies on additive manufacturing or other flexible processes, the expenses involved are significantly lower, making it a more affordable option for prototype development.

Improved Design Flexibility

During the prototype development phase, designers often need to make changes based on testing and feedback. Rapid tooling allows for greater design flexibility, as it is easier to modify prototypes without significant delays or cost increases. If a design change is required, the prototype can be quickly updated and tested again, leading to better final products that meet customer expectations.

Enhanced Precision and Quality

Although rapid tooling is a faster and more cost-effective process, it does not compromise on the precision and quality of the prototypes. Modern rapid tooling techniques, such as 3D printing and CNC machining, allow for high-accuracy and fine detail in prototype production. This level of precision is critical for ensuring that prototypes function as intended and meet the necessary specifications for later production.

Reduced Risk

The iterative nature of rapid tooling allows for more testing and adjustments during the prototyping stage. This helps identify potential design flaws early on, minimizing the risk of costly mistakes in later stages of production. By catching issues before full-scale manufacturing, companies can avoid expensive rework and production delays.

Ability to Test Functional Prototypes

Rapid tooling techniques, such as injection molding, can produce fully functional prototypes that mimic the final product’s performance. This enables businesses to test the actual functionality of the prototype before committing to mass production. Functional testing ensures that the product performs as expected, and any necessary adjustments can be made prior to large-scale production.

Better Collaboration and Communication

The speed and accessibility of rapid tooling foster better collaboration between design teams, engineers, and manufacturers. Since prototypes can be produced quickly and modified easily, stakeholders can provide feedback and see tangible results faster. This helps streamline communication, align goals, and reduce misunderstandings during the product development process.

Rapid tooling has revolutionized the way prototypes are developed, offering a wide range of benefits for businesses looking to improve their product design process. By reducing costs, speeding up production, and allowing for quick iterations, rapid tooling accelerates the journey from concept to finished product. For companies eager to innovate and bring products to market faster, rapid tooling is an invaluable tool that enhances both efficiency and quality in prototype development.