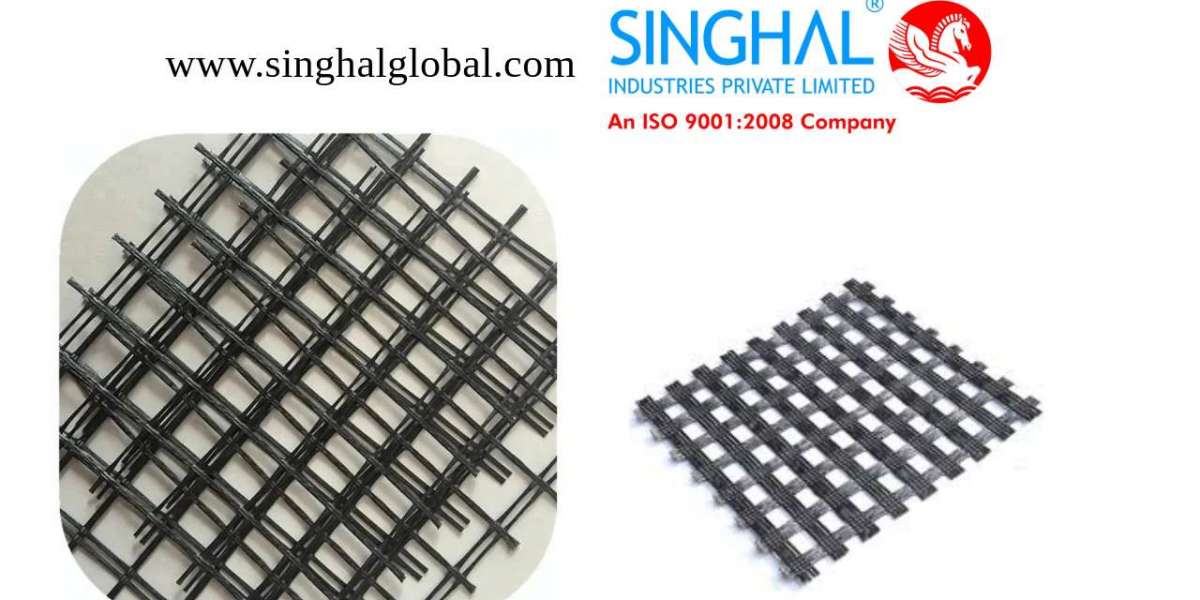

Polyester Geogrid is a high-strength, versatile, and cost-effective geosynthetic material primarily used in civil engineering, construction, and road reinforcement projects. These geogrids are manufactured using high-quality polyester yarns that are coated with a protective polymer, making them durable and resistant to harsh environmental conditions. As demand for sustainable and efficient construction solutions grows, Polyester Geogrid Price companies are consistently innovating to meet modern project requirements.

What is the Actual Use of Polyester Geogrid?

The primary purpose of Polyester Geogrid is to provide reinforcement to soils, pavements, and other construction surfaces. It is specifically designed to stabilize weak subgrades and improve load distribution. By using geogrids in infrastructure projects, engineers can extend the lifespan of roads, railways, and embankments while minimizing maintenance costs. This material is especially essential in regions prone to soil erosion, heavy traffic loads, or unstable terrain. Polyester Geogrid Suppliers provide a range of solutions tailored to various project needs.

The Purpose of Polyester Geogrid in Construction

Polyester Geogrids serve as reinforcement elements in multiple construction projects, ensuring structural stability and strength. They are used to:

Stabilize Subgrades: Weak or poorly compacted soil can lead to deformation or collapse of infrastructure. Geogrids provide tensile strength to support the weight of heavy loads.

Improve Pavement Performance: By incorporating geogrids under pavements, cracks and deformations are significantly reduced.

Slope Protection: Polyester Geogrids prevent soil erosion on embankments and slopes, making them vital in road construction and railways.

Retaining Wall Reinforcement: They enhance the strength and durability of retaining walls by evenly distributing loads.

The purpose-driven design of this material ensures reliable performance across a variety of construction challenges.

Benefits of Polyester Geogrid

Polyester Geogrids offer numerous benefits that make them a preferred choice in modern construction. These include:

High Tensile Strength: Polyester Geogrids possess exceptional tensile strength, allowing them to withstand heavy loads without deforming.

Cost-Effective Solution: The use of geogrids reduces the need for expensive soil replacement and maintenance.

Easy Installation: The lightweight and flexible structure of Polyester Geogrid simplifies handling and installation on-site.

Durability and Chemical Resistance: These geogrids are resistant to biological degradation and chemical exposure, ensuring long-term performance.

Eco-Friendly Construction: By reducing the volume of construction materials needed, Polyester Geogrid minimizes environmental impact.

Applications of Polyester Geogrid in Infrastructure

Polyester Geogrid is widely used across multiple industries due to its versatility and durability. Key applications include:

Road Construction and Pavement Reinforcement: Geogrids are placed beneath asphalt or concrete pavements to prevent cracking and rutting. They help distribute the load evenly, improving the structural integrity of roads.

Railway Reinforcement: Polyester Geogrids are used in railway embankments to stabilize tracks and minimize settlement.

Retaining Walls and Slope Stability: These geogrids reinforce retaining walls, preventing soil erosion and structural collapse.

Ground Stabilization for Airports and Industrial Yards: Geogrids strengthen ground surfaces to bear the load of heavy machinery and aircraft.

Landfill and Earthwork Projects: In landfill sites, Polyester Geogrid prevents soil displacement and enhances slope stability.

Factors Affecting Polyester Geogrid Price

The Polyester Geogrid Price depends on several key factors, including:

Material Quality: High-quality geogrids made from premium polyester yarns tend to be more expensive.

Grid Strength and Size: The tensile strength and grid dimensions impact the overall cost.

Application Requirements: Specialized geogrids designed for unique construction projects may have a higher price.

Market Demand and Suppliers: Prices can vary depending on the availability and competitive pricing strategies of Polyester Geogrid Suppliers.

It is essential to consult trusted manufacturers to get the best pricing for bulk orders and project-specific needs.

Choosing the Best Quality Polyester Geogrid

To ensure optimal performance, it is crucial to choose high-quality Polyester Geogrid from reputable manufacturers. Consider the following when selecting geogrids:

Tensile Strength: Verify the tensile strength requirements based on your project load conditions.

Coating and Durability: Ensure the geogrid has a protective polymer coating for long-term resistance to environmental conditions.

Supplier Reliability: Collaborate with trusted Polyester Geogrid Manufacturer companies to guarantee product quality and timely delivery.

Project Compatibility: Choose geogrids that align with the specifications and requirements of your project.

By focusing on these aspects, construction professionals can achieve the desired performance and durability.

Conclusion

Polyester Geogrid plays a critical role in ensuring the stability, durability, and efficiency of infrastructure projects. From road construction to slope protection, its versatile applications and numerous benefits make it an indispensable material for engineers and contractors. By choosing reliable Polyester Geogrid Suppliers and manufacturers, construction professionals can achieve high-quality outcomes at competitive prices. As the demand for sustainable and resilient infrastructure continues to rise, Polyester Geogrid remains a key solution for addressing modern construction challenges.

Frequently Asked Questions (FAQs)

1. What are the main uses of Polyester Geogrid?

Polyester Geogrid is primarily used for soil stabilization, pavement reinforcement, retaining wall construction, and slope protection. It enhances structural stability in road construction, railways, and earthwork projects.

2. How does Polyester Geogrid improve pavement performance?

Polyester Geogrid prevents cracks and rutting by evenly distributing heavy loads across the pavement surface. This reinforcement improves the overall lifespan and durability of roads.

3. What factors influence the Polyester Geogrid Price?

The price is determined by material quality, tensile strength, grid size, project requirements, and market demand. Consulting trusted Polyester Geogrid Suppliers can help secure competitive pricing.

4. Why is Polyester Geogrid preferred in construction projects?

Polyester Geogrid is lightweight, durable, and cost-effective. It provides high tensile strength, easy installation, and long-term performance, making it ideal for modern construction applications.