When it comes to advanced surface cleaning technology, laser cleaning machines have become a top choice across multiple industries. From automotive and aerospace to historical restoration and manufacturing, laser cleaning offers a fast, eco-friendly, and precise method of removing rust, paint, and contaminants from surfaces. But as interest in this technology grows, one common question remains: What affects the laser cleaning machine price?

Understanding the Value Behind the Price

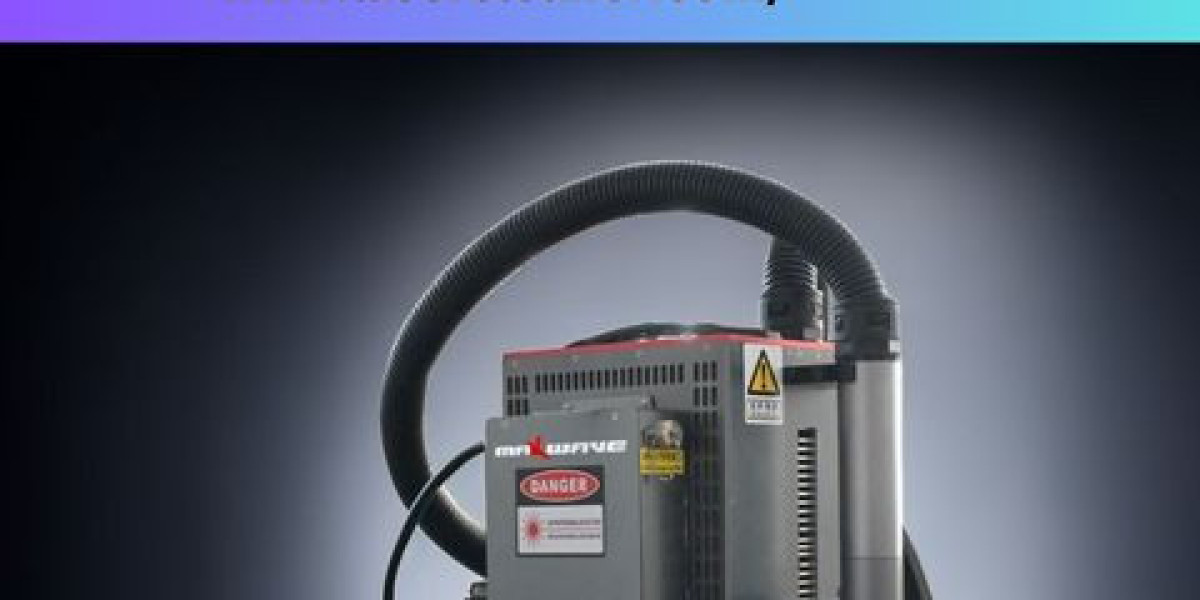

Laser cleaning machines are high-tech devices that use focused laser beams to clean surfaces without causing damage. The price of these machines can vary significantly depending on several factors, including power output, laser type, portability, and brand reputation.

For example, entry-level handheld models suitable for small-scale operations may start around $3,000 to $10,000. These are ideal for occasional use or for businesses just beginning to explore laser cleaning. On the other end of the spectrum, industrial-grade systems with higher power capabilities and automation features can range from $20,000 to over $100,000. These advanced systems are built for continuous, heavy-duty applications and often include features like real-time monitoring, software control, and robotic integration.

Why Invest in a Laser Cleaning Machine?

Though the initial investment may seem high, the long-term benefits of using a laser cleaner often outweigh the cost. Traditional cleaning methods like sandblasting, chemical solvents, or abrasive pads can lead to wear and tear on materials, increased labor, and added safety concerns. In contrast, laser cleaning is contactless, chemical-free, and requires minimal maintenance.

Additionally, the precision of laser cleaning reduces the risk of damaging delicate components, making it ideal for industries where accuracy is critical. Over time, this leads to reduced operational costs, improved workplace safety, and enhanced product quality.

Finding the Right Fit

Choosing the right laser cleaner depends on your specific needs. Consider factors such as:

Surface type: Are you cleaning metal, stone, plastic, or another material?

Level of contamination: Heavy rust or delicate residue?

Usage frequency: Daily industrial use or occasional restoration projects?

Required precision: Do you need pinpoint accuracy or large-surface coverage?

Answering these questions will help you narrow down your options and better evaluate what you’re paying for. It's not just about finding the lowest price — it’s about finding the best value for your specific application.

For those interested in comparing options and understanding the latest pricing, laser cleaning machine price resources are available from trusted suppliers like LaserCleaner. Their product range is tailored to meet different industrial and commercial needs while offering transparent pricing and support.

Conclusion

Laser cleaning machines are reshaping how we think about surface preparation and maintenance. While the upfront cost may vary, the advantages in efficiency, safety, and long-term savings make these machines a worthwhile investment. Whether you're a small business or a large industrial operator, understanding the laser cleaning machine price helps you make a smart and informed decision.laser cleaning machine price