Market Overview

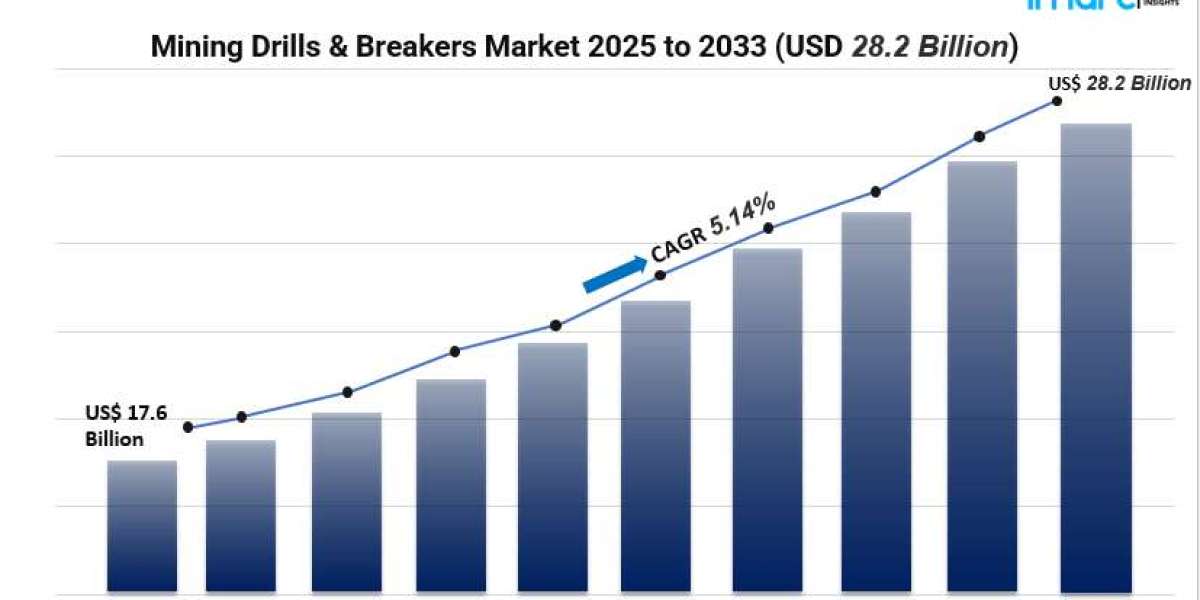

The global mining drills and breakers market reached a valuation of USD 17.6 billion in 2024 and is projected to grow to USD 28.2 billion by 2033, exhibiting a CAGR of 5.14% during the forecast period. This growth is driven by increasing demand for minerals, technological advancements, stringent safety regulations, expansion of underground mining, exploration of unconventional resources, cost optimization, geopolitical factors, sustainable practices, and adoption of renewable energy.

Study Assumption Years

- Base Year: 2024

- Historical Years: 2019–2024

- Forecast Years: 2025–2033

Mining Drills & Breakers Market Key Takeaways

- Market Size & Growth: The market was valued at USD 17.6 billion in 2024 and is expected to reach USD 28.2 billion by 2033, growing at a CAGR of 5.14%.

- Regional Performance: Asia-Pacific currently dominates the global market, driven by rapid industrialization and urbanization in countries like China, India, and Australia.

- Application Segmentation: Metal mining holds the largest market share, attributed to the essential role of metals in various industries, including construction, automotive, and electronics.

- Sales Channel: Original Equipment Manufacturer (OEM) is the leading sales channel, indicating a preference for new equipment over aftermarket services.

- Technological Advancements: Integration of AI, IoT, and automation in mining equipment enhances operational efficiency, safety, and productivity.

- Sustainability Focus: Stringent environmental regulations are pushing for the adoption of eco-friendly drilling and breaking solutions.

Market Growth Factors

Developments in Mining Equipment Technology

The mining industry is undergoing significant transformations as it embraces cutting-edge technologies like Artificial Intelligence, the Internet of Things, and automated drilling machines. These innovations enable companies to keep an eye on operations in real time, anticipate maintenance needs, and reduce the need for direct human oversight. As a result, both efficiency and safety at mining sites see a boost. Take autonomous drills, for instance—they can operate in hazardous areas with minimal human intervention, which not only cuts down on labor costs but also enhances safety. Leveraging these technologies is crucial for reaching remote or difficult-to-access locations, allowing for the exploration and extraction of minerals from places that were once hard to reach.

Strict Environmental and Safety Regulations

Around the globe, governments are tightening regulations regarding safety and environmental standards in mining. These regulations compel companies to utilize equipment that generates less noise, emits fewer pollutants, and minimizes risks. For example, the Mine Safety and Health Administration, part of the U.S. Department of Labor, conducts regular inspections to ensure safe working conditions. Such regulations drive mining companies to invest in modern drilling and breaking equipment that complies with safety standards and protects the environment. This trend is fostering market growth.

Growing Interest in Metals and Minerals

The rapid industrial growth and urban sprawl in countries like China and India have significantly increased the demand for minerals and metals. These essential materials are crucial for various industries, including construction, automotive, and electronics. As a result, mining companies are expanding their operations and investing in advanced drilling equipment and breaking machines to meet this surging demand. Additionally, the exploration of unconventional resources and investments in infrastructure development are further propelling the market.

Request for a sample copy of this report: https://www.imarcgroup.com/mining-drills-breakers-market/requestsample

Market Segmentation

By Type

- Drills: Essential for initial mineral extraction, drills are widely used across various mining operations, making them indispensable for efficient resource access.

- Breakers: Used for breaking rocks and other hard materials, breakers are crucial in mining operations for material size reduction.

By Product

- Rotary Drills: Utilized for drilling large holes in hard rock formations, rotary drills are known for their efficiency and durability.

- Crawler Drills: Equipped with tracks for mobility, crawler drills are suitable for uneven terrains and are commonly used in surface mining.

- Rock Breakers: Designed to break large rocks into smaller pieces, rock breakers are essential for material handling in mining sites.

- Hydraulic Breakers: Powered by hydraulic systems, these breakers offer high efficiency and are used for demolishing hard structures.

- Others: Includes various other drilling and breaking equipment used in specific mining applications.

By Application

- Metal Mining: Involves the extraction of metal ores like iron, copper, and gold, which are vital for various industries.

- Mineral Mining: Focuses on the extraction of non-metallic minerals used in construction and manufacturing.

- Coal Mining: Pertains to the extraction of coal, a primary energy source for electricity generation and industrial processes.

By Sales Channel

- Original Equipment Manufacturer (OEM): Refers to the direct purchase of new equipment from manufacturers, indicating a preference for the latest technology.

- Aftersales: Includes services and parts provided after the initial sale, such as maintenance and repairs.

By Region

• North America (United States, Canada)

• Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

• Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

• Latin America (Brazil, Mexico, Others)

• Middle East and Africa

Regional Insights

In the mining drills and breakers sector, the Asia-Pacific region is leading the charge, thanks to the swift industrialization and urbanization in countries like China, India, and Australia. The area's abundant mineral resources and substantial investments in mining contribute to its top position. China, in particular, is notable for its extensive coal mining activities and strong governmental support for mining initiatives.

Recent Developments & News

The mining drills and breakers market is undergoing significant transformations, driven by new technologies that emphasize automation and sustainability. Companies are now incorporating AI and IoT technologies into their machinery, enabling real-time monitoring and proactive maintenance planning. These advancements aim to enhance operational efficiency and improve worker safety. Simultaneously, there is a growing emphasis on developing greener machines to comply with stringent environmental regulations. Electric and hybrid equipment are gaining traction to reduce emissions and align with global sustainability goals.

Key Players

- Atlas Copco AB

- Boart Longyear

- Casagrande S.p.A.

- Caterpillar Inc.

- Doosan Corporation

- Epiroc AB

- Furukawa Co. Ltd.

- Geodrill Limited

- Komatsu Ltd.

- Sandvik AB

- Soosan Heavy Industries Co. Ltd.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=6466&flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services. IMARC offerings include a thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: +1-631-791-1145