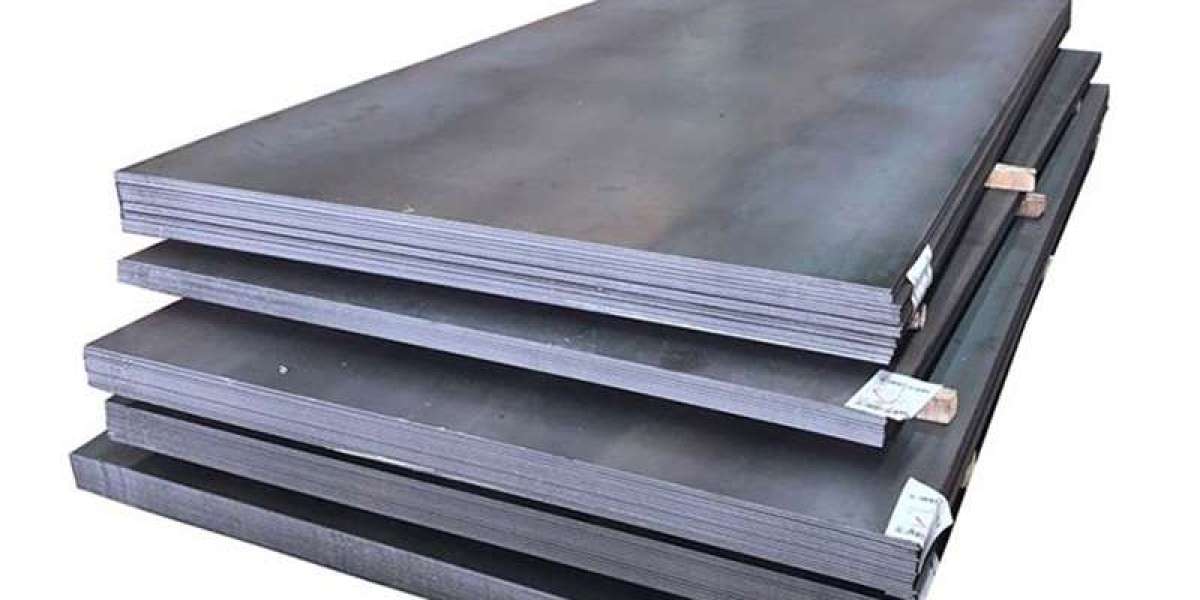

High carbon steel plates and sheets have become indispensable in heavy machinery manufacturing due to their exceptional strength and wear resistance properties. With carbon content typically ranging from 0.60% to 1.00%, these materials offer the durability required to withstand extreme operational stresses in mining, construction, and industrial equipment applications.

The superioraluminium pipe load-bearing capacity of high carbon steel plates makes them ideal for structural components in heavy machinery. Excavator buckets, bulldozer blades, and crane components benefit from the material's ability to maintain structural integrity under repetitive impact and abrasive conditions. Some manufacturers have developed specialized high carbon steel formulations with added chromium or manganese to further enhance wear resistance in particularly demanding environments like mineral processing or quarry operations.

In sheet form, high carbon steel finds extensive use in manufacturing industrial cutting tools and wear plates. The material's hardness after proper heat treatment allows it to maintain sharp edges far longer than lowerbrass pipe carbon alternatives. Many equipment manufacturers now utilize laser-cut high carbon steel sheets to produce precision components with complex geometries for specialized machinery. The combination of machinability in the annealed state and exceptional final properties after heat treatment makes these materials versatile solutions for engineers designing heavy-duty equipment components.