Market Overview:

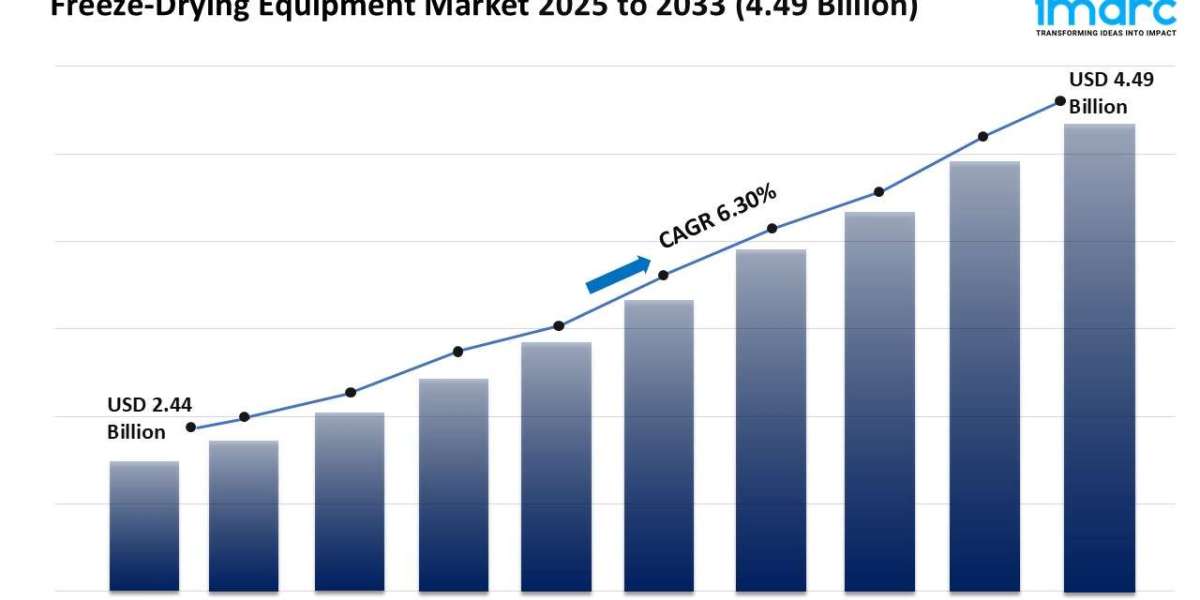

The freeze-drying equipment market is experiencing rapid growth, driven by rising food preservation demand, technological advancements drive efficiency, and expanding pharmaceutical applications. According to IMARC Group’s latest research publication, “Freeze-Drying Equipment Market Size, Share, Trends and Forecast by Dryer Type, Scale of Operation, Application, and Region, 2025-2033”, The global freeze-drying equipment market size was valued at USD 2.44 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 4.49 Billion by 2033, exhibiting a CAGR of 6.30% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/freeze-drying-equipment-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Factors Affecting the Growth of the Freeze-Drying Equipment Industry:

- Rising Food Preservation Demand

The freeze-drying equipment industry is rapidly progressing due to demand for food preservation. Consumers and industries are often focused on products with longevity without losing nutritional value or flavors. Freeze-drying technology will reduce moisture stabilizing quality products that benefit food manufacturers and health-conscious consumers alike. Ready-to-eat meals and high-quality pet food sales have also contributed to the uptick in demand for freeze-dried products. Industries appreciate freeze-drying technology because the process retains delicate flavors and nutrients during drying, leading to better investment in new and advanced freeze-drying systems by addressing quality requirements and consumer preferences.

- Technological Advancements Drive Efficiency

Improvements in freeze-drying machinery are changing the landscape of the marketplace by improving productivity and scalability. Current equipment has systems built with automations, energy-consumption savings, and more accurately controlled processes to lower operational costs and processing times. Improvements within freeze-drying technology will benefit many sectors, such as pharmaceuticals and biotechnology, where precision in processing materials is paramount, and potential safety issues arise when working to retain protection for sensitive materials such as vaccines and biologicals. Improved designs also support better access to sustainable operations. Equipment that is developing by manufacturers to lead the way in freeze-drying includes it's compact, and flexible use cases allowing it to be used by potentially smaller and upcoming businesses to utilize freeze-drying technology. Additionally, there is growing demand for quality shelf-stable products across almost every industry.

- Expanding Pharmaceutical Applications

A major market driver is the pharmaceutical industry's increasing dependence on freeze-drying equipment. Lyophilization provides the greatest stability of drugs, vaccines, and biologics, lengthening the shelf life of a product while maintaining the effectiveness of the ingredient. The rising need for biologics, as well as personalized medicines, has led to increased investments and the use of targeted freeze-drying equipment tailored to meet the requirements of the pharmaceutical industry. Manufacturers are producing equipment that is customizable, with precise temperature controls, temperature mapping, and vacuum controls to satisfy regulatory requirements. Further, the growing production of biopharmaceutical drugs in developing countries is increasing demand for equipment because companies are looking for a reliable process to produce high-quality products that meet the product integrity required to scale and often adhere to global quality standards.

We explore the factors propelling the freeze-drying equipment market growth, including technological advancements, consumer behaviors, and regulatory changes.

Leading Companies Operating in the Freeze-Drying Equipment Industry:

- Azbil Corporation

- Cuddon Freeze Dry

- GEA Group Aktiengesellschaft

- Harvest Right, LLC

- HOF Sonderanlagenbau GmbH

- Labconco Corporation

- Martin Christ Gefriertrocknungsanlagen GmbH

- Millrock Technology, Inc.

- OPTIMA packaging group GmbH

- Shanghai Tofflon Science and Technology Co. Ltd.

- Thermo Fisher Scientific

Freeze-Drying Equipment Market Report Segmentation:

By Dryer Type:

- Tray Style Freeze Dryers

- Manifold Freeze Dryers

- Rotary Freeze Dryers

Tray-style freeze dryers dominate pharmaceutical use for large-batch processing, while manifold dryers serve small-scale labs, and rotary dryers handle agitation-sensitive materials.

By Scale of Operation:

- Industrial Scale Freeze Dryer

- Pilot Scale Freeze Dryer

- Laboratory Scale Freeze Dryer

Industrial-scale freeze dryers lead due to high-volume efficiency and regulatory compliance, while pilot and lab-scale units cater to R&D and testing needs.

By Application:

- Food Processing and Packaging

- Pharmaceutical and Biotechnology

- Biomedical Engineering

- Others

Food processing drives demand with freeze-drying’s shelf-life extension benefits, while pharmaceuticals and biotech rely on it for sensitive drug formulations.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia-Pacific holds the largest share due to rapid industrialization, growing food/pharma sectors, and increasing demand for advanced preservation technologies.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145