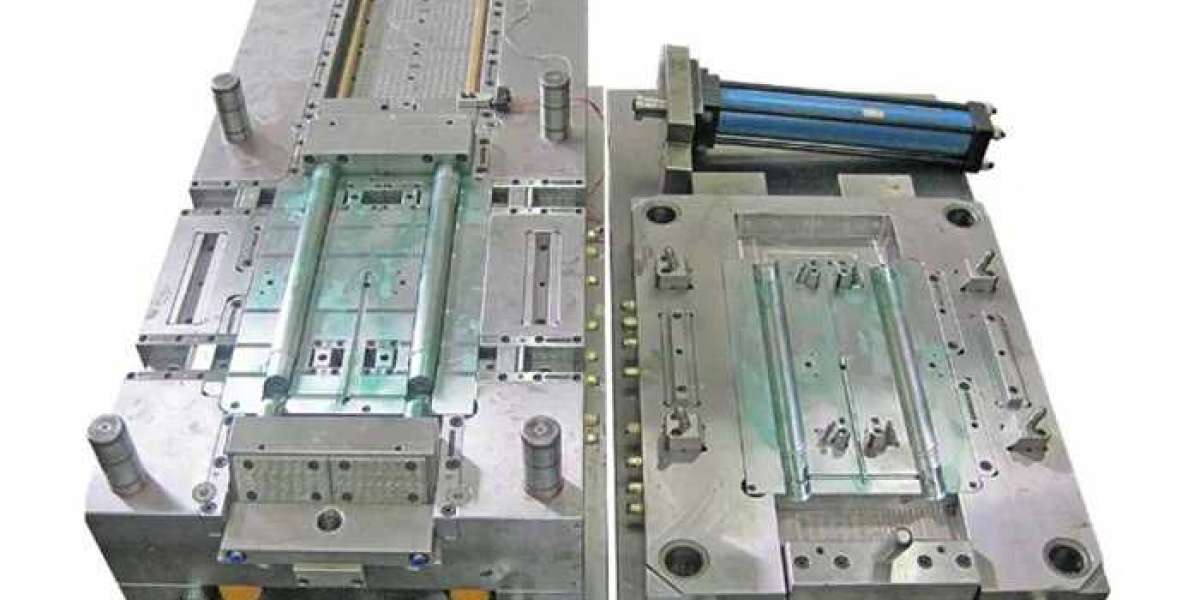

Vacuum cleaners have become an indispensable tool for maintaining cleanliness and hygiene in our homes and workplaces. Behind the sleek design and powerful suction lies a complex manufacturing process that involves the use of injection molds. In this blog post, Xuzhong will explore the key features of vacuum cleaner injection molds and how they contribute to the efficiency and precision of the manufacturing process.

Material Selection:

The first crucial feature of a vacuum cleaner injection mold is the selection of materials. High-quality molds are typically made from durable and robust materials such as steel, aluminum, or stainless steel, depending on the requirements and budget of the manufacturer. These materials offer excellent heat resistance, wear resistance, and dimensional stability, ensuring that the mold can withstand the demands of high-volume production.

Design Flexibility:

Vacuum cleaner injection molds are designed with flexibility in mind. The molds are created to accommodate various complex shapes, sizes, and intricacies that are required for the production of different components of a vacuum cleaner. This design flexibility allows manufacturers to produce a wide range of parts, including the main body, attachments, nozzles, filters, and other intricate components of the vacuum cleaner.

Precision and Accuracy:

Precision and accuracy are essential in the injection molding process to ensure consistent and flawless production. Vacuum cleaner injection molds are designed with meticulous attention to detail in order to meet these requirements. The molds undergo a rigorous design and manufacturing process, including computer-aided design (CAD), computer numerical control (CNC) machining, and high-precision tooling. This ensures that each molded part is produced with the utmost precision, resulting in a perfect fit and optimum performance.

Rapid Prototyping:

To keep up with the ever-evolving demands of the market, vacuum cleaner manufacturers often need to develop and test new designs quickly. Vacuum cleaner injection molds offer the advantage of rapid prototyping, allowing manufacturers to create functional prototypes efficiently. This process enables them to assess the form, fit, and functionality of the design before committing to full-scale production. Rapid prototyping not only saves time and resources but also reduces the risk of errors, ensuring that only the best designs move forward.

Multiple Cavity Molds:

Efficiency and productivity are vital in the manufacturing process, especially for high-volume production runs. Vacuum cleaner injection molds often incorporate multiple cavity designs, allowing multiple parts to be produced simultaneously. This significantly increases productivity, reduces cycle times, and minimizes overall production costs. With the ability to produce multiple parts in a single cycle, manufacturers can meet market demands more efficiently and optimize their production capacity.

Venting Systems:

During the injection molding process, air can get trapped inside the mold cavities, resulting in incomplete or imperfectly formed parts. To address this issue, vacuum cleaner injection molds are equipped with venting systems. These venting systems allow air to be safely and effectively expelled from the mold cavities, ensuring that the final products are free from defects and have uniform quality.

Cooling Systems:

Efficient cooling is crucial in the injection molding process to ensure proper mold solidification and minimize cycle times. Vacuum cleaner injection molds are designed with advanced cooling systems, including cooling channels, baffles, and conformal cooling technologies. These systems facilitate uniform and controlled cooling of the mold, resulting in faster cycle times, improved part quality, and increased production efficiency.

Maintenance and Longevity:

Vacuum cleaner injection molds are subject to wear and tear over time due to the high-pressure and high-temperature environments they operate in. However, manufacturers employ various maintenance strategies to prolong the lifespan of the molds. This includes regular cleaning, lubrication, and inspection to identify and address any potential issues. By maintaining the molds in optimal condition, manufacturers can ensure consistent quality and maximize the efficiency of their production processes.

Conclusion:

The production of vacuum cleaners requires meticulous attention to detail and high precision, which can be achieved through the use of vacuum cleaner injection molds. The features discussed above, including material selection, design flexibility, precision, rapid prototyping, multiple cavity molds, venting and cooling systems, as well as maintenance practices, all contribute to the efficiency, accuracy, and longevity of the injection molding process.

With the advancement of injection molding technology, manufacturers can produce vacuum cleaners with improved performance, durability, and aesthetics. By investing in high-quality vacuum cleaner injection molds and optimizing their production processes, manufacturers can meet market demands, reduce costs, and deliver superior products to consumers.

https://www.xuzhongmold.com/Features-of-vacuum-cleaner-injection-mold.html